1. Introduction When working on an electrical project, it’s common to see cables and conduits purchased together. In fact, many...

Read More

Blog

How to Bend Electrical Conduit Without a Bender

Ctubeofficialchina – July 22, 2025

1. Introduction “Can I bend electrical conduit without a special tool?” That’s a common question from people working on electrical...

Read More

What to Know Before Installing Exposed Conduit

Ctubeofficialchina – July 5, 2025

1. Introduction When we think about electrical conduit, we often imagine it hidden behind walls or ceilings. But in many...

Read More

A Complete Guide to PVC Elbows and Bends in Electrical Conduit Systems

Ctubeofficialchina – July 5, 2025

1. Introduction In any electrical conduit system, straight runs of pipe are just the beginning. To navigate corners, avoid structural...

Read More

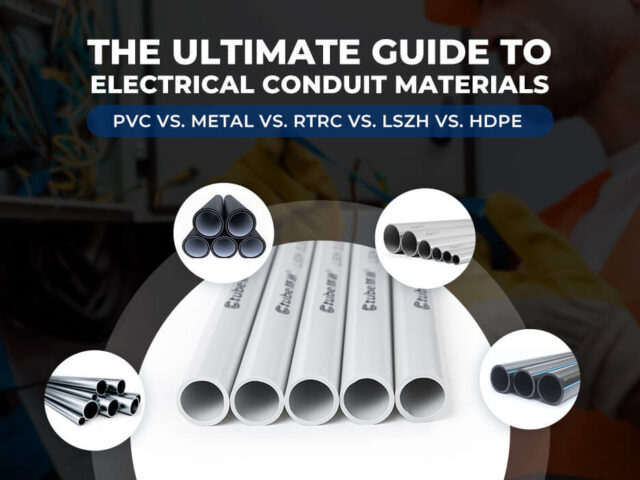

PVC vs. Metal vs. RTRC vs. LSZH vs. HDPE, The Ultimate Guide to Electrical Conduit Materials (2025)

Ctubeofficialchina – April 2, 2025

1. Introduction An electrical conduit pipe is a protective tubing system designed to house and safeguard electrical wiring from mechanical...

Read More

Ultimate Guide to Cable Trunking: Design Types, Sizes, Regulations, and Best Practices

Ctubeofficialchina – March 31, 2025

1. Introduction to Cable Trunking Systems Cable trunking is an essential component of electrical installations, designed to house and protect...

Read More

IEC 61386 Standard PVC Conduit – Everything You Need to Know

Ctubeofficialchina – March 24, 2025

1. Introduction When it comes to electrical installations, selecting the right conduit is crucial for ensuring safety, durability, and performance....

Read More

Top 10 PPR Pipe Manufacturers and Suppliers in China

Ctubeofficialchina – March 1, 2025

1. 联塑 (LESSO Group) Introduction: Established in 1986 and listed on the Hong Kong Stock Exchange (HKEX: 2128), LESSO Group...

Read More

Top 10 PPR Pipe Manufacturers and Suppliers in the World

Ctubeofficialchina – March 1, 2025

PPR (Polypropylene Random Copolymer) pipes have become a cornerstone in modern infrastructure due to their durability, resistance to corrosion, and...

Read More

Guide to Selecting the Best Conduit for Your Fiber Optic Project

Ctubeofficialchina – February 1, 2025

1. Introduction 1.1 Overview of Fiber Optic Installations Fiber optic technology is the backbone of modern communication, enabling high-speed internet,...

Read More

Endless Options For Your Specific Needs

Ctube focuses on the plastic electrical conduit field, around the customer’s demand for products, technology and services.

We always take additional measures to make our customers satisfied with the quality, efficiency and marketability of our products. With high quality and a wide range of products, we have established long-term cooperation with many customers from different areas of the world.

Request a Quote

Ready to Work Together? Build a project with us!