IEC 61386 Standard PVC Conduit – Everything You Need to Know

1. Introduction

When it comes to electrical installations, selecting the right conduit is crucial for ensuring safety, durability, and performance. Among the various conduit materials available, PVC (Polyvinyl Chloride) conduit stands out as a popular choice due to its flexibility, corrosion resistance, and ease of installation. The IEC 61386 standard provides essential guidelines for conduit systems’ classification and performance requirements, ensuring they meet global safety and reliability standards.

Whether you’re working on a residential, commercial, or industrial project, understanding the specifications and benefits of conduits under the IEC 61386 standard is key to making informed decisions. This article dives deep into the details of conduit systems as outlined by the IEC 61386, and compares PVC conduit with traditional metal conduits. By the end of this guide, hope you’ll have a comprehensive understanding of conduit classifications, performance tests, and best practices for choosing the right system for your electrical projects.

Let’s start with the title in first chapter, followed by a detailed articulation on IEC and the IEC 61386 standard.

2. Understanding IEC and IEC 61386 Standard

2.1 What is the IEC?

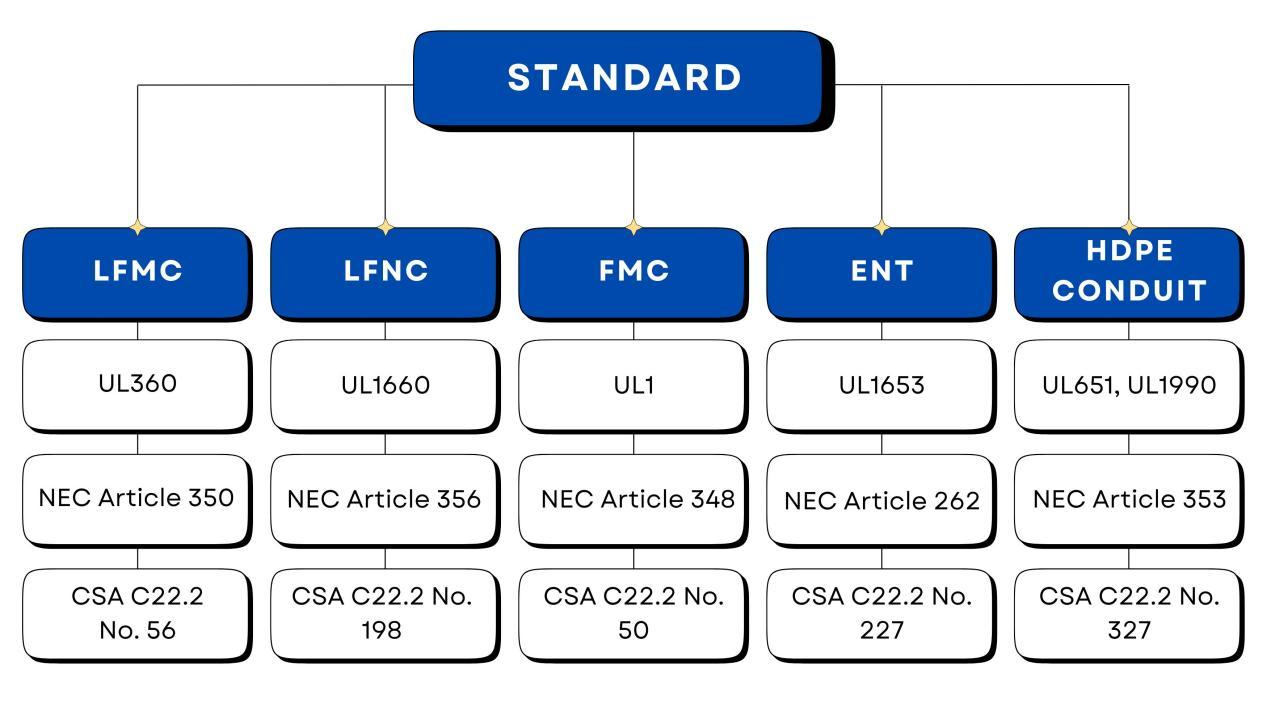

The International Electrotechnical Commission (IEC) is a global standards organization that prepares and publishes international standards for all electrical, electronic, and related technologies. Founded in 1906, the IEC plays a crucial role in ensuring the safety, quality, and interoperability of electrical products and systems across the world. Its standards are widely adopted and recognized by governments, manufacturers, and regulatory bodies, promoting international consistency in the design, production, and performance of electrical products.

Among its various standards, the IEC plays a leading role in developing criteria for systems such as conduit systems, wiring accessories, and electrical cables. The organization works closely with national standards bodies, ensuring that IEC standards are implemented globally, helping industries maintain a high level of operational safety and technical compatibility.

2.2 What is IEC 61386 Standard?

Among its key standards, IEC 61386 is widely regarded as the go-to reference for conduit systems, which specifically focuses on the classification and performance requirements of conduit systems used to protect and route electrical wiring.

2.2.1 Countries and Markets That Adopt IEC 61386

China

China has translated the IEC 61386 standard into the national standard GB/T 20041.1-2015, which governs conduit systems in the domestic market. This adaptation ensures that local manufacturers and professionals comply with internationally recognized safety and performance standards for conduit systems, while aligning with the global market requirements.

European Union (EU)

In the European Union, countries such as Germany, France, and others widely adopt the IEC 61386 standard through CE marking. This ensures that conduit systems meet essential European safety and performance standards, facilitating the free movement of goods across EU member states. The recognition of IEC 61386 in the EU helps manufacturers and suppliers ensure their conduit products meet rigorous market requirements.

Other IEC Member Countries

Australia, Japan, and various other IEC member countries often use IEC 61386 as the foundation for their national technical regulations or industry specifications. These countries may adapt the IEC standard to better suit local conditions, but the core principles of the IEC 61386 standard remain a basis for their technical requirements. The widespread adoption of IEC 61386 helps standardize conduit systems, ensuring safety, quality, and compatibility across international borders.

2.2.2 What Conduit Types IEC 61386 Standard Mentioned?

Metallic conduits – Known for their high mechanical strength and grounding capabilities.

Non-metallic conduits – Made from materials like PVC, which offer corrosion resistance and electrical insulation.

Composite conduits – Combining properties of both metallic and non-metallic materials for specialized applications.

The standard outlines performance requirements under normal and extreme conditions, including exposure to mechanical pressure, thermal stress, and chemical exposure. It also defines the testing methods used to evaluate compliance with these performance criteria.

Additionally, IEC 61386 recognizes that certain conduit systems may be suitable for use in hazardous environments. In such cases, extra requirements must be met to ensure safety and compliance.

2.2.3 Classification of Conduits Under IEC 61386

IEC 61386 is divided into several parts, each addressing specific types of conduit systems and their unique requirements:

IEC 61386-21 – Rigid conduit systems: Defines the requirements for conduits that maintain a fixed shape under mechanical stress.

IEC 61386-22 – Pliable conduit systems: Covers conduits that can be bent or flexed without returning to their original shape.

IEC 61386-23 – Flexible conduit systems: Specifies the properties of conduits that can flex and bend repeatedly without damage.

IEC 61386-24 – Conduit systems buried underground: Outlines the special requirements for conduits exposed to soil pressure, moisture, and temperature changes.

IEC 61386-25 – Conduit fixing devices: Defines the performance requirements for components used to secure conduit systems in place.

This classification system allows manufacturers, installers, and inspectors to select the appropriate conduit system for specific applications, ensuring consistency and compliance with international safety and performance standards.

Here we have introduce some details about IEC and IEC 61386 Standard.

In the following section, we will take a closer look at IEC 61386-1, which is a crucial part of the IEC 61386 series and sets out the general requirements for conduit systems.

3. Introduce Key Requirements in IEC 61386 Standard

IEC 61386-1 provides detailed guidelines and performance criteria for conduits and conduit fittings used to protect and manage insulated conductors and cables in electrical installations or communication systems. These systems are designed for use in environments with electrical voltages up to 1,000 V AC and 1,500 V DC, making them suitable for both residential and industrial applications.

3.1 General Requirements & Test Conditions

Here we provide a summary of the general requirements for conduit systems and the conditions under which they are tested.

3.1.1 General Requirements

Design and Construction: Conduit and conduit fittings must be designed and constructed to ensure reliable performance in normal use. They must provide adequate protection for both the user and surrounding areas.

Assembly and Protection: When assembled according to the manufacturer’s instructions, conduits and fittings must provide mechanical protection, and where necessary, electrical protection for the cables and conductors inside.

Joint Integrity: The protective properties of the joint between the conduit and conduit fitting must meet or exceed the protection levels declared for the entire conduit system.

Durability: Conduits and fittings must withstand stresses encountered during transport, storage, installation, and regular application without compromising their performance.

Compliance: Compliance with these requirements is verified by conducting the specified tests outlined in the standard.

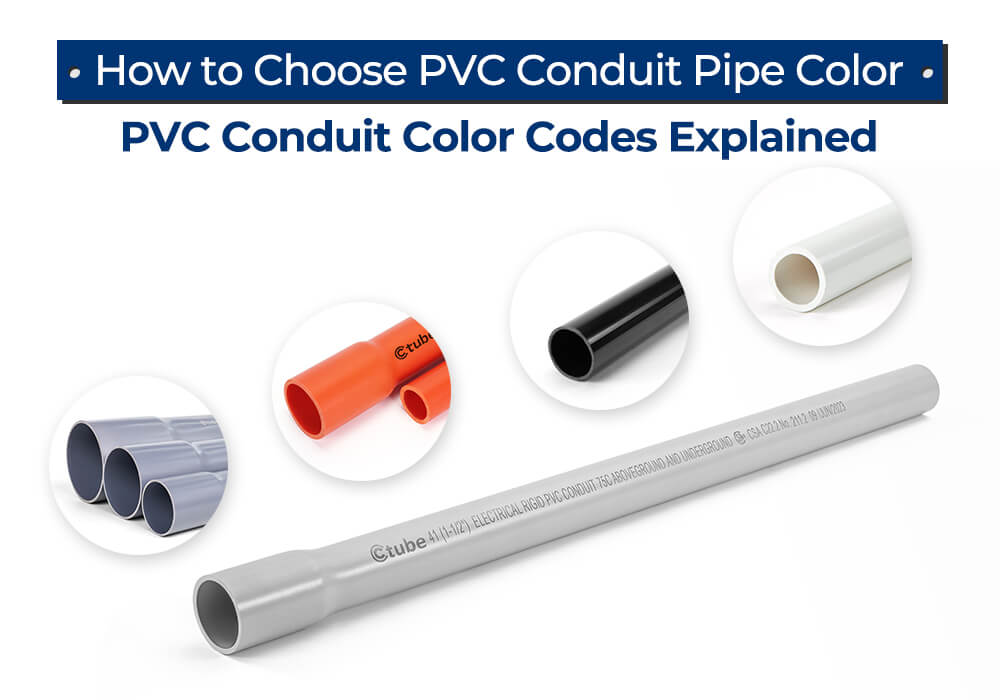

3.1.2 General Conditions for Tests

Type Tests: All tests conducted according to the standard are type tests. Conduit systems with the same classification (though colors may vary) must be considered as the same product type for testing purposes.

Ambient Temperature: Unless otherwise stated, tests should be conducted at an ambient temperature of 20 ± 5°C.

Sample Conditions: Tests are generally performed on three new samples taken from one length of conduit. Non-metallic or composite conduits and fittings should be conditioned for at least 240 hours at 23 ± 2°C and 40-60% relative humidity before testing.

Condition of Samples: Samples must be clean, with all parts mounted as they would be in normal use. Conduit systems should be assembled as per the manufacturer’s instructions, especially when force is needed to assemble joints.

Test Failures and Actions: If one sample fails to meet the test requirements, the remaining tests will be conducted on additional samples as necessary. A failure in one test requires a complete retest of all samples to ensure compliance.

3.2 Classification Criteria According to IEC 61386

In IEC 61386 standard, conduit systems are classifies based on mechanical, electrical, temperature, external influences, and flame resistance properties. It does not involve actual testing but establishes how conduits should be classified according to specific properties. But essentially, classification helps users choose the right conduit type based on their application. Here we provide some details for you to better understand.

3.2.1 Mechanical Properties

Conduit systems are classified according to their ability to withstand different mechanical stresses.

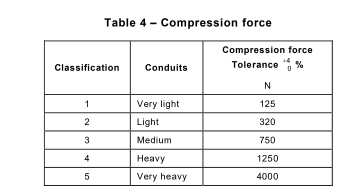

Resistance to Compression: Ranges from Very Light, Light, Medium, Heavy, and Very heavy.

Resistance to Impact: Categorized from Very Light to Very Heavy, indicating how well the conduit can handle physical shocks or impacts.

Resistance to Bending: Classifications include Rigid, Pliable, Self-recovering, and Flexible, showing how easily the conduit can bend or return to its original shape.

Tensile Strength: Ranges from Very Light to Very Heavy, defining the material’s ability to resist stretching under tension.

Suspended Load Capacity: Classifications from Very Light to Very Heavy indicate the amount of weight the conduit can support when suspended.

3.2.2 Temperature Ranges

Conduit systems are classified based on their resistance to temperature extremes:

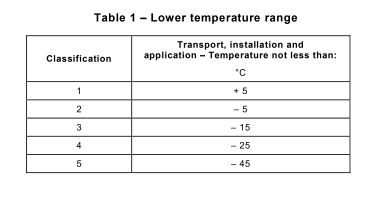

Lower Temperature Range: Classifications from +5°C to -45°C, defining the minimum temperature at which the conduit can be transported, installed, and used.

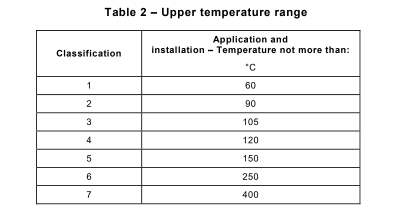

Upper Temperature Range: Classifications range from 60°C to 400°C, indicating the maximum temperature the conduit can withstand during application and installation.

3.2.3 Electrical Characteristics

Conduit systems must meet specific electrical requirements:

With Electrical Continuity Characteristics: This classification ensures that the conduit maintains electrical continuity, providing grounding and protection.

With Electrical Insulating Characteristics: Indicates the conduit’s ability to act as an insulator, preventing electrical current from passing through.

3.2.4 Resistance to External Influences

The conduit’s ability to withstand external environmental factors is categorized as follows:

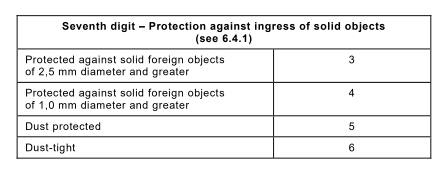

Protection Against Ingress of Solid Objects: Protection level is defined according to IEC 60529 standards, with at least IP3X protection.

Protection Against Ingress of Water: Classifications are based on the ability to prevent water from entering the conduit, with a minimum IPX0 rating.

Resistance Against Corrosion: Conduits may be classified with or without protection against corrosion, depending on the material and intended use.

3.2.5 Flame Propagation

Conduit systems are classified by their resistance to flame propagation:

Non-flame Propagating: Conduit that does not allow flames to spread along its length.

Flame Propagating: Conduit that may allow flame to spread, though it typically resists fire to some extent.

Additionally, in countries like Australia and Austria, conduits may be classified for low acid gas emissions, indicating their ability to withstand certain environmental hazards.

3.3 Marking and Documentation Requirements

Here we also summary the marking requirements in IEC 61386. Understanding the marking and documentation requirements of conduit systems is essential for both suppliers and customers.

For suppliers, it ensures compliance with international standards, improves traceability, and builds brand reputation by providing clear product identification and reliable information.

For customers, it guarantees they receive high-quality products that meet specific performance criteria, aids in correct product selection, and ensures easy installation and support. Proper marking facilitates a smooth transaction and confidence in the safety and reliability of the products.

Manufacturer Identification: Each conduit must be marked with the manufacturer’s or responsible vendor’s name or trademark and a product identification mark (e.g., catalogue number or symbol) for easy identification.

Classification Code: The conduit or its smallest supplied package must be marked with a classification code. This code, in accordance with Annex A, should include at least the first four digits and be clearly visible.

Self-Recovering Conduits: Self-recovering conduits must also bear the classification code on the conduit or the smallest supplied package, with a clear label showing at least the first five digits.

Compatibility and Classification: The manufacturer is responsible for indicating the compatibility of parts within a conduit system and must provide full classification in the product’s literature, along with necessary information for proper transport, storage, installation, and use.

Flame Propagation: Conduits made of flame-propagating materials must be marked with a specific symbol (flame icon) along their entire length, ideally at intervals no longer than 1 meter. If the package prevents the mark from being seen, it should be labeled on the packaging instead.

Earthing Facilities: Conduits with earthing facilities must be marked with the IEC 60417-5019 symbol for protective earth, but this should not be placed on removable parts like fittings.

Durability and Legibility: Markings must be durable, clear, and legible, checked through normal or corrected vision. The marking surface should also undergo rubbing tests to ensure durability, with specific procedures for testing marking endurance under various conditions.

Inspection Compliance: All markings must be inspected to ensure they comply with the outlined standards. This includes visual checks and rubbing tests with cotton soaked in solvents like n-hexane 95%, ensuring they remain intact under normal handling and wear.

3.4 Dimensions and Construction Requirements for Conduit Systems

Understanding the dimensions and construction requirements of conduit systems is crucial for ensuring safe installation and reliable performance.

3.4.1 Dimensions Compliance

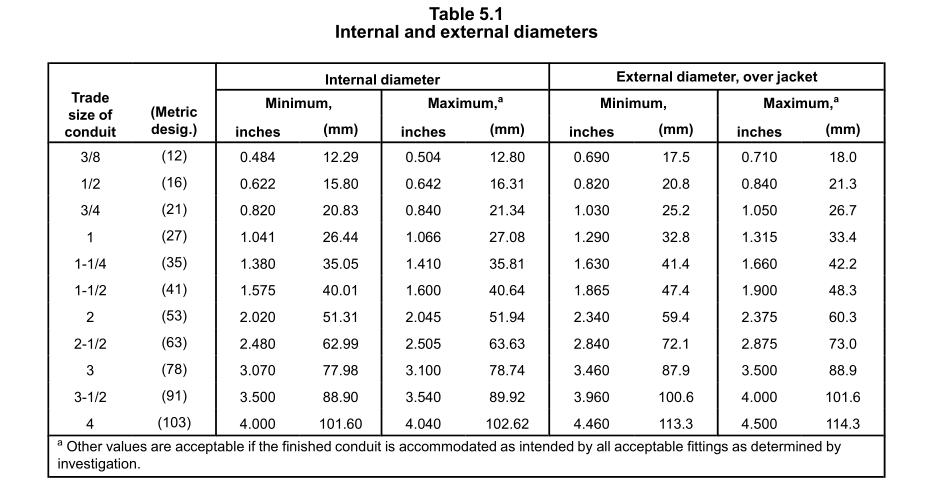

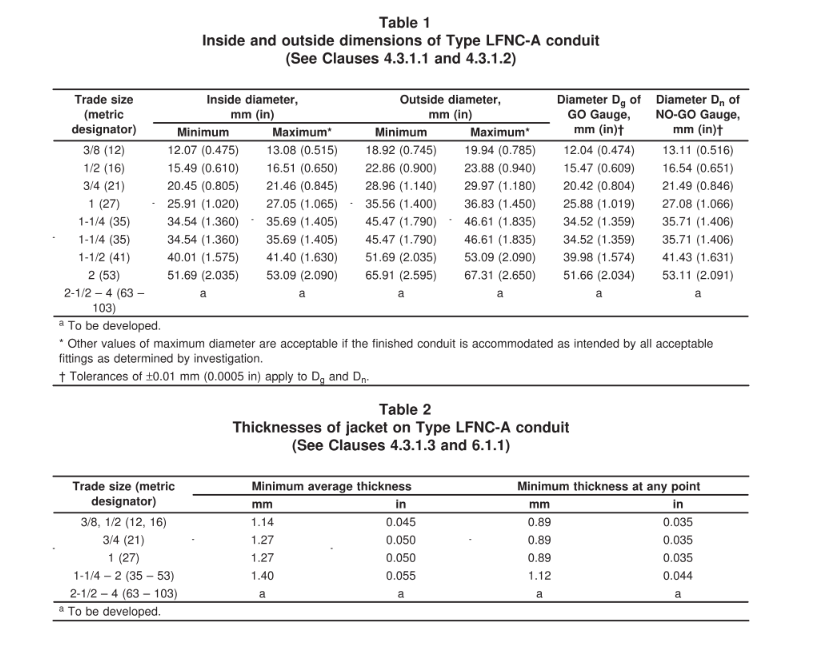

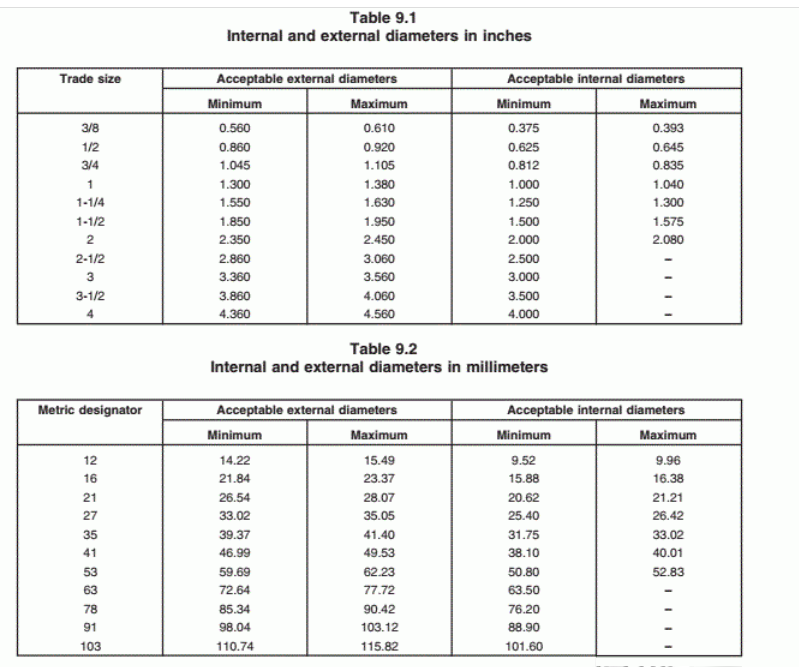

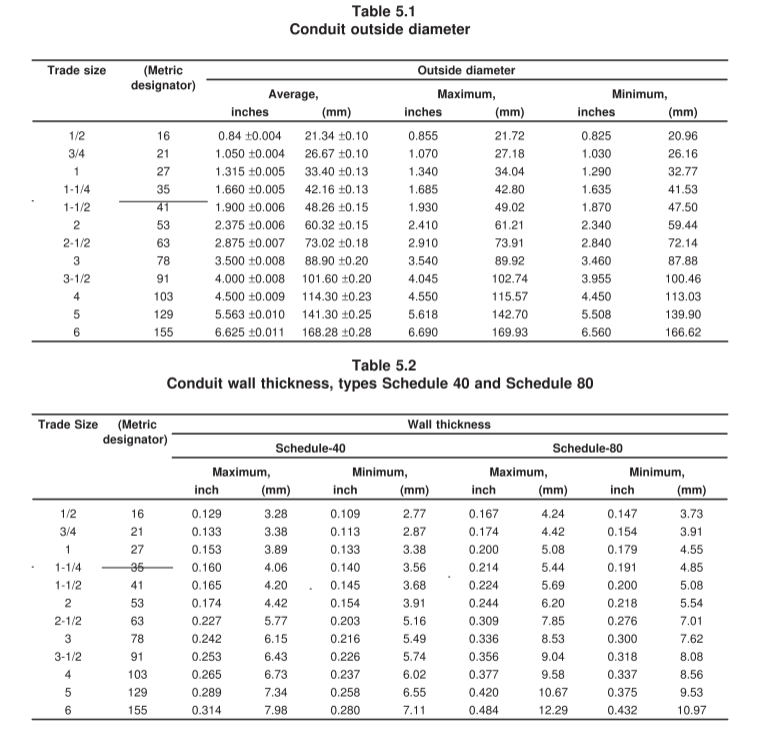

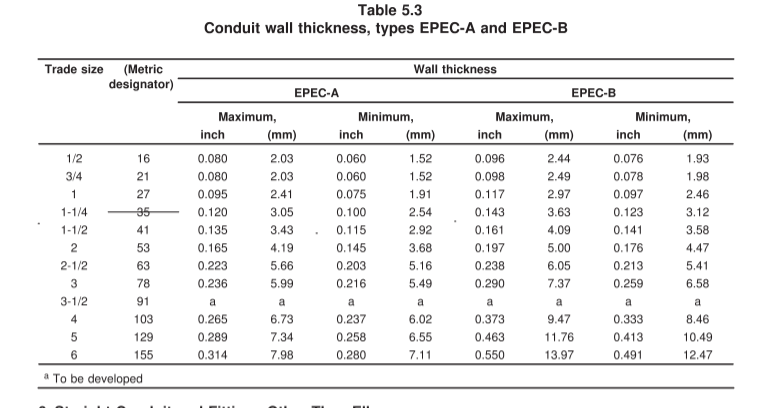

Thread and External Diameters: Conduit threads and external diameters must comply with IEC 60423 standards. This ensures that all thread sizes and diameters are uniform and meet the necessary specifications for compatibility and safety.

Other Dimensions: For all other dimensions, conduit systems should meet the requirements outlined in Part 2 of IEC 61386, ensuring consistency and standardized measurements across different types of conduit systems.

3.4.2 Construction Standards

Sharp Edges and Burrs: Conduit systems must be designed and constructed without sharp edges, burrs, or surface projections that could damage cables or harm installers and users during handling and installation.

Screws: Screws used to attach components or covers must comply with specific guidelines:

- ISO Metric Threads: All screws must use ISO metric threads to prevent damage to cable insulation during installation.

- Thread-Cutting Screws: Thread-cutting screws should not be used to avoid damaging the conduit or fittings.

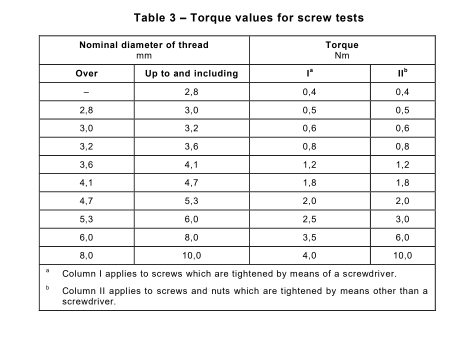

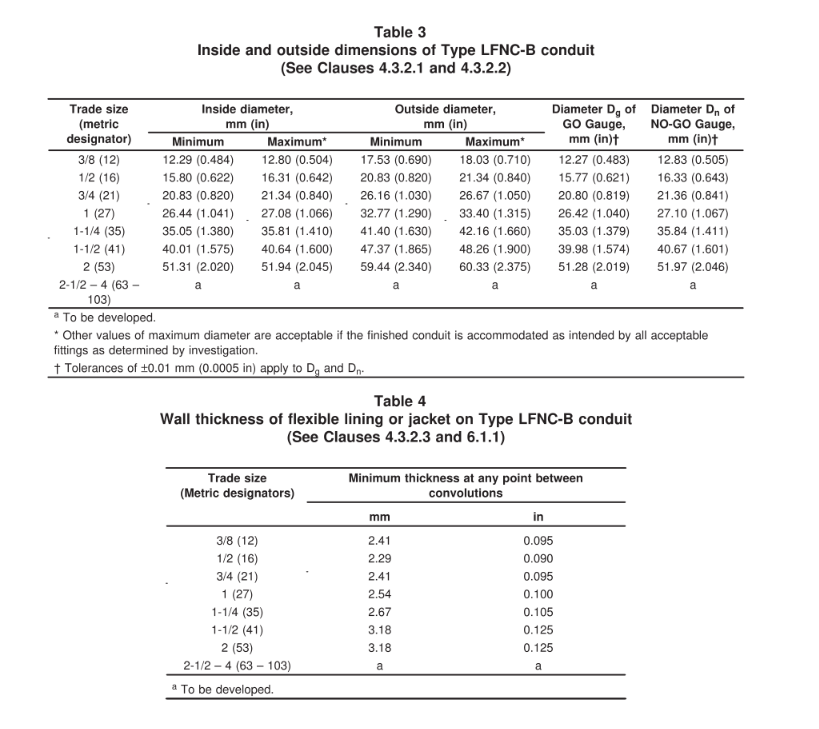

Screw Fixing and Torque: Screws for securing conduit parts must be able to withstand mechanical stresses during installation and normal use. For fixing with preformed thread screws, the screws should be tightened and loosened 10 times (or 5 times for specific cases) without sustaining damage. Thread-forming screws should be tested for torque values as specified in Table 3, ensuring proper installation and durability without damaging the screw or the threaded part.

Material and Resistance: Any material inside the joint (e.g., rubber, fiber) exposed to external influences must provide the same level of protection as the conduit or fitting itself. This ensures the system’s overall resistance to environmental factors.

Disassembly: For conduit systems assembled without threads, manufacturers should specify whether the system can be disassembled and how this can be done safely, ensuring ease of maintenance and flexibility.

4. Detailed Tests of Conduit in IEC 61386 Standard

4.1 Mechanical Properties Required in IEC 61386

Conduit systems must exhibit adequate mechanical strength to handle the forces they are subjected to during use. These systems, depending on their classification, should not crack or deform to the extent that insulated conductors or cables become difficult to insert. They must also be capable of supporting equipment if used as mounts, both during installation and operation. They should be verified through tests in the following. So in the following, we will make detailed introduction about this tests.

For better understanding, unless otherwise specified, the relevant tests mentioned below are typically required for all types of electrical conduits, including metallic, non-metallic, and composite conduits.

4.1.1 Compression Test

Samples of conduit (200 ± 5 mm long) are tested for compression by applying a gradually increasing force, reaching the value specified for each conduit classification. After the force has been applied, the sample’s outer diameter is measured again to check for any deformation. The difference between the initial and flattened diameter should not exceed 25% of the original dimension. The force is then removed, and the sample is checked for cracks. This test ensures the conduit can withstand compression during installation and use.

4.1.2 Impact Test

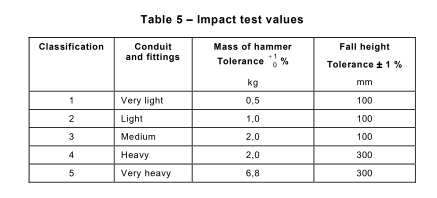

This test evaluates the impact resistance of conduit systems by subjecting twelve samples (200 ± 5 mm long) to a specified impact. The samples are first conditioned at the required temperature, and then a hammer is dropped onto the sample to simulate potential real-world impacts. The mass of the hammer and fall height vary depending on the conduit classification, with heavier classes requiring more significant impact tests. After the test, the conduit must show no significant damage, cracks, or deformation.

4.1.3 Bending Test

The Bending Test is conducted to ensure that both metallic and non-metallic conduits can withstand bending during installation without damage.

For metallic conduits (sizes 16, 20, and 25), the samples are bent to an angle of 90° ± 5° with an inside radius up to six times the nominal diameter. After bending, the conduit should show no cracks, openings, or excessive distortion, and the seams must remain intact. For conduits with welded seams, both sides of the bend are tested to ensure the conduit remains structurally sound.

For non-metallic conduits, the bending process is similar, with a length of 500 mm ± 10 mm and conducted at a temperature of 12 ± 2°C. These samples must also show no visible damage, such as cracks or distortion, after the test. The conduit should be able to return to its straight form under its own weight without requiring any initial speed.

For Composite conduits, they are declared by the manufacturer as being bendable are tested as metallic and non-metallic conduit.

4.1.4 Flexing Test

The Flexing Test is conducted to ensure that conduit systems, particularly flexible conduits, can withstand repeated movement without damage. The test is performed on six samples, with three tested at the minimum and three at the maximum declared temperatures for transport, application, and installation.

For flexible conduits, the test ensures that the product is suitable for transport and installation at both ambient and maximum temperatures as per the manufacturer’s specifications. If the conduit is only suitable for ambient temperature flexing, the test is conducted at 20 ± 2°C.

The samples are fixed to an oscillating member and subjected to a back-and-forth motion at a frequency of 5,000 flexes over a 180° angle. The test is performed at a speed of 40 ± 5 flexes per minute. After completing the flexing cycle, the samples must show no visible cracks or damage under normal or corrected vision, confirming the conduit’s durability under repeated motion.

This test ensures that flexible conduits maintain their integrity during installation and handling, making them suitable for environments requiring frequent movement or bending.

4.1.5 Collapse Test

The Collapse Test evaluates the ability of non-metallic and composite conduits to withstand external pressures without deforming or collapsing. Metallic conduits are not subject to this test.

For non-metallic conduits, which are classified as bendable by the manufacturer, the samples are bent and then fixed to a rigid support using four straps, as outlined in the manufacturer’s instructions. The samples are then placed in a heating cabinet at a specified temperature for 24 ± 15 minutes to condition them properly. After this period, the conduit is positioned so that the straight portions of the sample are at a 45° angle to the vertical, ensuring they maintain their integrity when subjected to external forces.

The test ensures that the conduit can withstand pressure without collapsing or distorting, maintaining its ability to protect the cables inside. This test is essential for non-metallic and composite materials to guarantee their durability under normal use conditions.

4.1.6 Tensile Test

The Tensile Test is conducted to measure the tensile strength of conduit systems. A sample consisting of a conduit and two fittings (or terminating conduit fittings) is assembled according to the manufacturer’s instructions, ensuring that the conduit length between fittings is at least 200 mm. When this length is not feasible, the test is conducted on two samples of conduit and fittings.

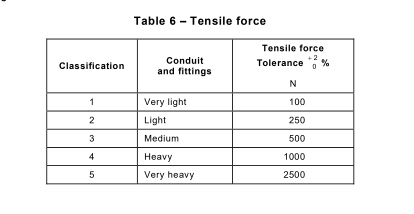

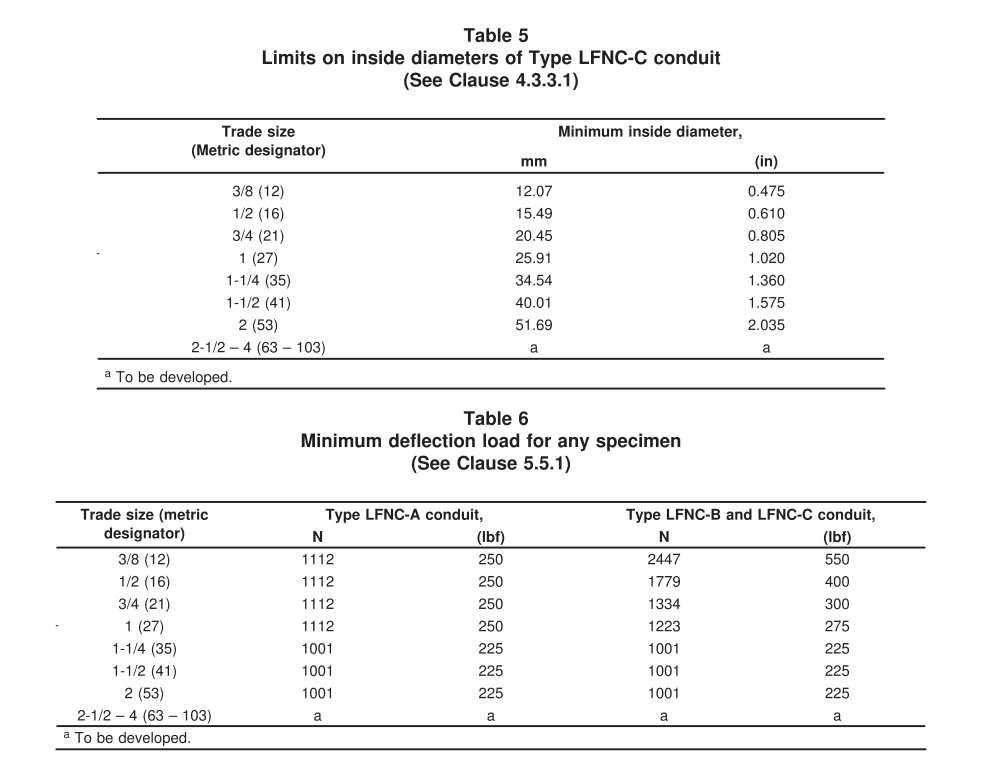

The test applies a uniformly increasing tensile force until it reaches the specified value in Table 6. The force is maintained for 2 minutes ± 10 seconds at 23 ± 2°C. After the test, the conduit and fittings must remain properly assembled, with no visible damage to the components when observed without magnification.

If the tensile strength of the system is not declared, the manufacturer must ensure that the system meets

the relevant standards for tensile strength according to the appropriate part of the IEC 61386 standard. The test ensures that the system will maintain its structural integrity during use without damaging the fittings or conduit under tensile force.

4.1.7 Suspended load test

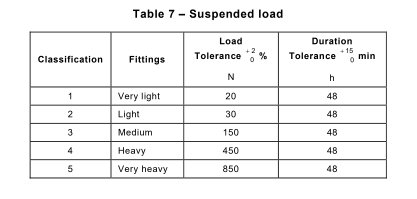

The Suspended Load Test evaluates the strength and durability of conduit fittings designed to support suspended loads. The fitting is secured to a rigid structure using a manufacturer-approved method, with the suspension means pointing downward. A specified load, based on the classification in Table 7, is applied for a duration of 48 hours.

To pass the test, the fitting must show no visible cracks or deformation that would impair its normal use. For non-metallic and composite conduit fittings, the test is conducted in a heating cabinet at the declared maximum operating temperature, with a tolerance of ±2°C.

4.2 Electrical Properties

4.2.1 Electrical Requirements

Continuity Testing (Metallic, Composite): Conduit systems declaring electrical continuity characteristics must be tested immediately after installation.

Bonding of Metallic Parts (Metallic, Composite): Metallic or composite conduits should be constructed to allow bonding of accessible metal parts. Compliance is checked by inspection.

Earthing (Metallic, Composite): Conductive parts of metallic or composite conduits that may become live in a fault must be properly earthed. Compliance is tested via bonding.

Insulation Strength (Non-metallic, Composite): Non-metallic and composite conduit systems must have adequate insulation resistance and electrical insulating strength. Compliance is tested through dielectric strength and insulation resistance tests.

4.2.2 Bonding Test (Metallic, Composite)

To assess the electrical continuity of metallic and composite conduit systems, a bonding test is performed by connecting 10 conduit pieces with fittings according to the manufacturer’s instructions. A current of 25 A at 50-60 Hz is applied through the system for 60 seconds, with the voltage drop measured to calculate resistance. The resistance must not exceed 0.1 Ω to ensure proper electrical bonding. If different types of fittings are used, the test must be repeated for each type. Additionally, any protective coatings that could interfere with conductivity should be removed before testing.

4.2.3 Dielectric Strength and Insulation Resistance (Non-metallic, Composite)

For non-metallic and composite conduit systems, insulation strength is tested by immersing samples in a saltwater solution. After soaking, a high-voltage test is conducted by gradually increasing the voltage to 2,000 V AC over 15 minutes and maintaining it for 5 seconds. The system is considered compliant if it withstands this voltage without tripping a 100 mA safety circuit. Insulation resistance is also measured after voltage application, and the system must exhibit a resistance of at least 100 MΩ to pass.

Conduit fittings undergo similar testing procedures. Samples are immersed in water for 24 hours, then dried before testing. The fittings are sealed with insulating material, and an electrode is inserted to simulate real installation conditions. After a high-voltage test, the insulation resistance must be greater than 5 MΩ to be considered compliant.

4.3 Thermal Properties

Non-metallic and composite conduits must demonstrate sufficient heat resistance. Compliance is determined through standardized testing procedures. Metallic conduits are not explicitly mentioned in this section, as metal typically has different thermal performance criteria.

The heating test follows the classification of the conduit’s declared compression rating. Samples of conduit (each 100 ± 5 mm) are heated for 4 hours and 5 minutes at the specified temperature (see Table 8) with a ±2°C tolerance.

After heating, a load is applied for 24 hours and 15 minutes using a 6.0 ± 0.1 mm steel rod, positioned perpendicularly to the conduit’s axis. The total applied load corresponds to the classification in Table 8, ensuring accurate mechanical stress simulation.

Once the load is removed, the conduit must allow an appropriately sized gauge to pass through under its own weight without external force. This test ensures the conduit retains its internal dimensions and structural integrity after thermal and mechanical stress.

4.4 Fire Hazard

Non-metallic and composite conduits are subject to all fire hazard tests, including glow wire and flame application assessments, to ensure they meet fire resistance standards. Metal conduits are not explicitly mentioned in the testing criteria.

4.4.1 Reaction to Fire

Conduit systems are not in direct contact with live parts, meaning they do not pose an immediate risk of fire initiation. However, their contribution to fire and flame spread must be evaluated, particularly for non-metallic and composite conduit fittings.

4.4.2 Contribution to Fire

Non-flame propagating conduit systems must have adequate resistance to flame spread. Compliance for non-metallic and composite conduit fittings is assessed through two main tests. The first is the Glow Wire Test, conducted per IEC 60695-2-11, where a heated wire at 750°C is applied to the conduit in a vertical position. The conduit passes if it does not exhibit visible flames or sustained glowing, or if any flames extinguish within 30 seconds after wire removal.

The second test applies a 1 kW flame, in accordance with IEC 60695-11-2. The conduit sample is placed vertically inside a metal enclosure with an open face to minimize external air interference. This test further evaluates the flame resistance of non-metallic and composite conduits under direct fire exposure.

4.4.3 Spread of Fire

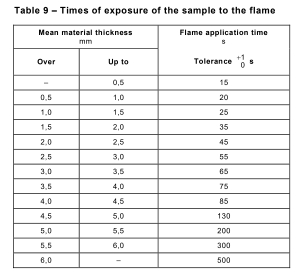

To ensure fire resistance, conduits are tested by direct flame exposure at a 45° angle within a controlled metal enclosure. Samples are securely mounted with clamps to prevent deformation during testing. A steel rod provides additional support for thinner conduits. Flame exposure time varies based on material thickness, as outlined in Table 9, with times ranging from 20 seconds for 0.5 mm thick conduits to 500 seconds for conduits up to 8 mm thick.

A conduit passes if it does not ignite, or if it self-extinguishes within 30 seconds after flame removal. Additionally, the test ensures that a tissue paper placed below the conduit does not ignite, and there is no charring or burning extending beyond 50 mm from the flame exposure point. These criteria ensure that non-metallic conduits meet fire safety standards, preventing flame spread in electrical installations.

4.4.4 Additional Fire Reaction Characteristics

In some regions, non-metallic conduits must also meet low acid gas emission standards.

In Australia, conduits classified as low acid gas emission are tested under IEC 60754-1, where emissions must not exceed 5 mg of hydrochloride acid per gram of material.

In Austria, similar regulations apply under IEC 60754-2. These requirements help reduce toxic gas emissions in the event of a fire, improving safety in enclosed environments.

4.5 External Influences

Enclosure protection applies to non-metallic and metallic materials, but corrosion resistance and testing focus on metallic systems, while non-metallic materials are not explicitly tested, they sometimes have an inherent resistance to chemicals.

4.5.1 Degree of Protection Provided by Enclosure

Conduit systems must provide adequate resistance to external influences based on the classification declared by the manufacturer, with a minimum requirement of IP30. Compliance is verified through specific tests assessing protection against solid objects and water ingress.

Protection Against Foreign Solid Objects: Assemblies made of conduit and fittings are tested to ensure no visible ingress of dust under normal vision. Tests follow IEC 60529 standards, and systems achieving numeral 5 or 6 are deemed compliant.

Protection Against Water Ingress: Conduit assemblies, including fittings, are tested for water resistance using IEC 60529 methods. For numerals 3 and 4, an oscillating tube test is used to assess water penetration. Systems rated numeral 1 and above pass if water ingress does not form visible droplets under normal vision.

4.5.2 Resistance to Corrosion

Both metallic and composite conduit systems, excluding screw threads, must demonstrate adequate resistance to corrosion for both interior and exterior applications. Corrosion resistance is classified into four levels:

Low Protection: Basic coatings like priming paint.

Medium Protection: Stove enamel or electro zinc plating.

Medium/High Protection: Enhanced coatings like Sherardizing.

High Protection: Heavy-duty coatings such as stainless steel or hot-dip zinc coating.

4.5.3 Corrosion Testing for Different Materials

For painted and zinc-coated steel and composite conduit systems, compliance is verified through specific tests.

Low Protection: Inspected for complete coverage.

Medium Protection: Cleaned with a solvent and immersed in a solution containing potassium ferricyanide and ammonium persulphate to test coating integrity.

High Protection: Undergoes degreasing, sulfuric acid immersion, and copper sulfate immersion to check corrosion resistance. The sample must be thoroughly cleaned after testing to remove residues.

For non-ferrous metallic and composite conduit systems, manufacturers must provide information on corrosion resistance. Some minor surface deposits, such as copper precipitation on screw threads, may be disregarded.

4.6 Electromagnetic Compatibility

Products covered by this standard are typically passive in terms of electromagnetic influences, including both emission and immunity. This means that, in normal use, the conduit systems do not emit electromagnetic interference (EMI) nor are they significantly affected by external electromagnetic signals.

However, when these products are installed as part of a wiring system, the entire installation may either emit electromagnetic signals or be influenced by external electromagnetic fields. The degree of influence will depend on the nature of the installation environment and the apparatus connected to the system. This means that electromagnetic compatibility (EMC) considerations are important for the overall installation, which includes the conduit systems.

Metallic and Non-metallic materials: The EMC requirements apply generally to both metallic and non-metallic conduit systems. However, metallic conduits may provide better shielding against electromagnetic interference compared to non-metallic conduits, which are more passive in terms of electromagnetic emissions and immunity.

5. Metallic Conduit vs Non-metallic PVC Conduit

Above, we have finished our introduction to the IEC 61386-1 Standard. By understanding the various tests and classifications outlined in the standard, you can make an informed choice between different materials such as non-metallic material PVC electrical conduits and metal conduit systems.

In the following, we will a more concrete and details in metal conduit and PVC conduit to help you make a better understanding.

5.1 Metal Conduit

From the above tests and requirements outlined in the IEC 61386-1 standard, we can clearly understand the advantages and disadvantages of metal conduit systems, as well as the different types of metal conduits available. These tests highlight key factors such as mechanical strength, fire resistance, and electromagnetic shielding, which are significant advantages of metal conduits.

However, they also reveal challenges such as weight, installation complexity, and susceptibility to corrosion.

In the following, we make a summarize for you to better understand.

5.1.1 Types of Metal Conduit

Rigid Metal Conduit (RMC) – A thick-walled steel conduit designed for maximum protection in industrial and commercial applications. It is highly durable but also heavy and requires threading for connections.

Intermediate Metal Conduit (IMC) – A lighter alternative to RMC, offering good protection with reduced weight. It is commonly used in outdoor and industrial settings.

Electrical Metallic Tubing (EMT) – A lightweight, thin-walled steel conduit that is easy to install and bend, making it ideal for commercial buildings and indoor applications. However, it provides less mechanical protection than RMC or IMC.

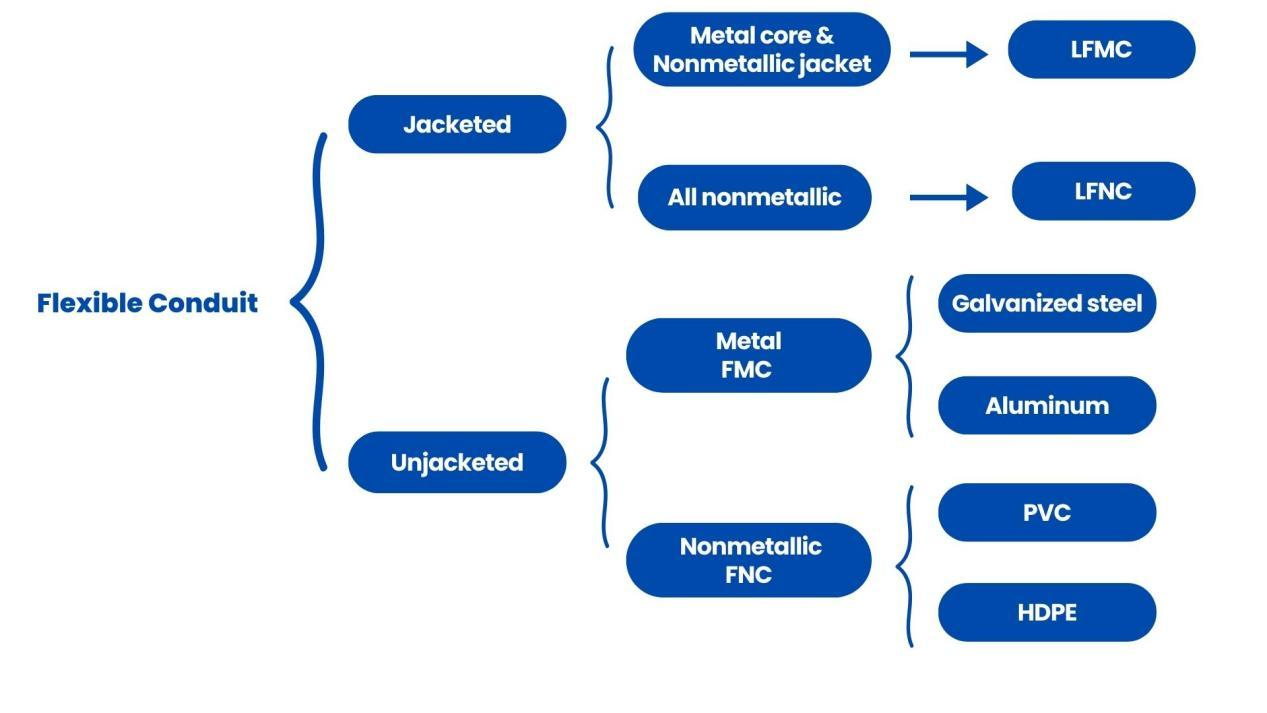

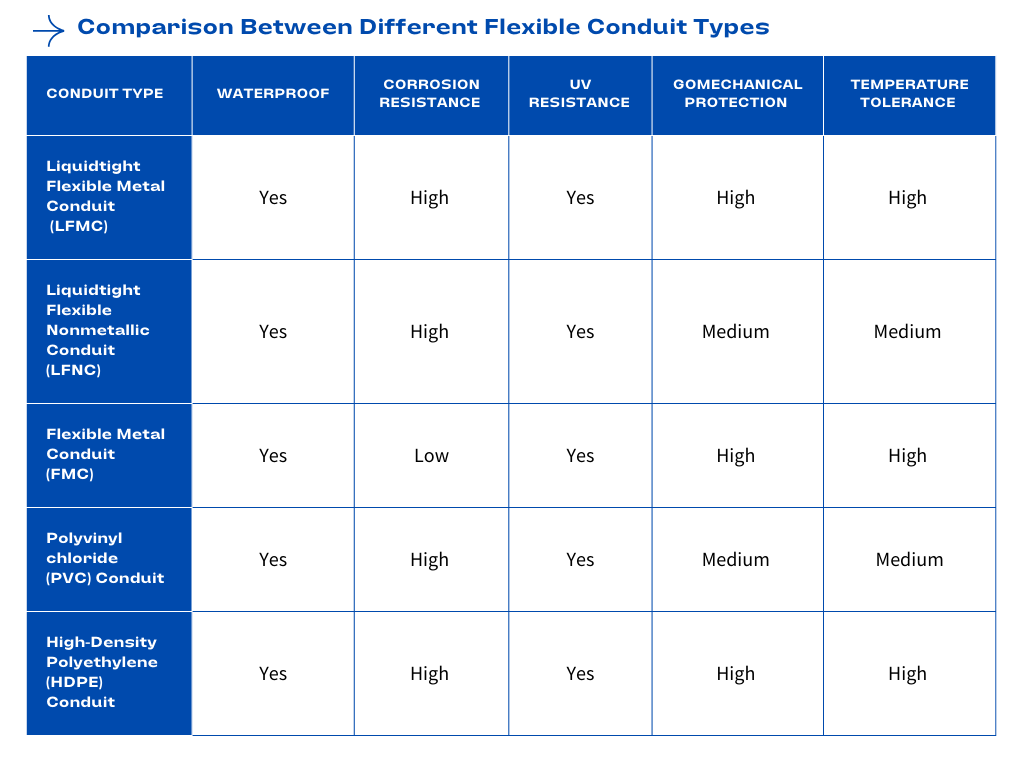

Flexible Metal Conduit (FMC) – Designed for applications requiring flexibility, FMC is used in areas where movement or vibration is a concern, such as motor connections.

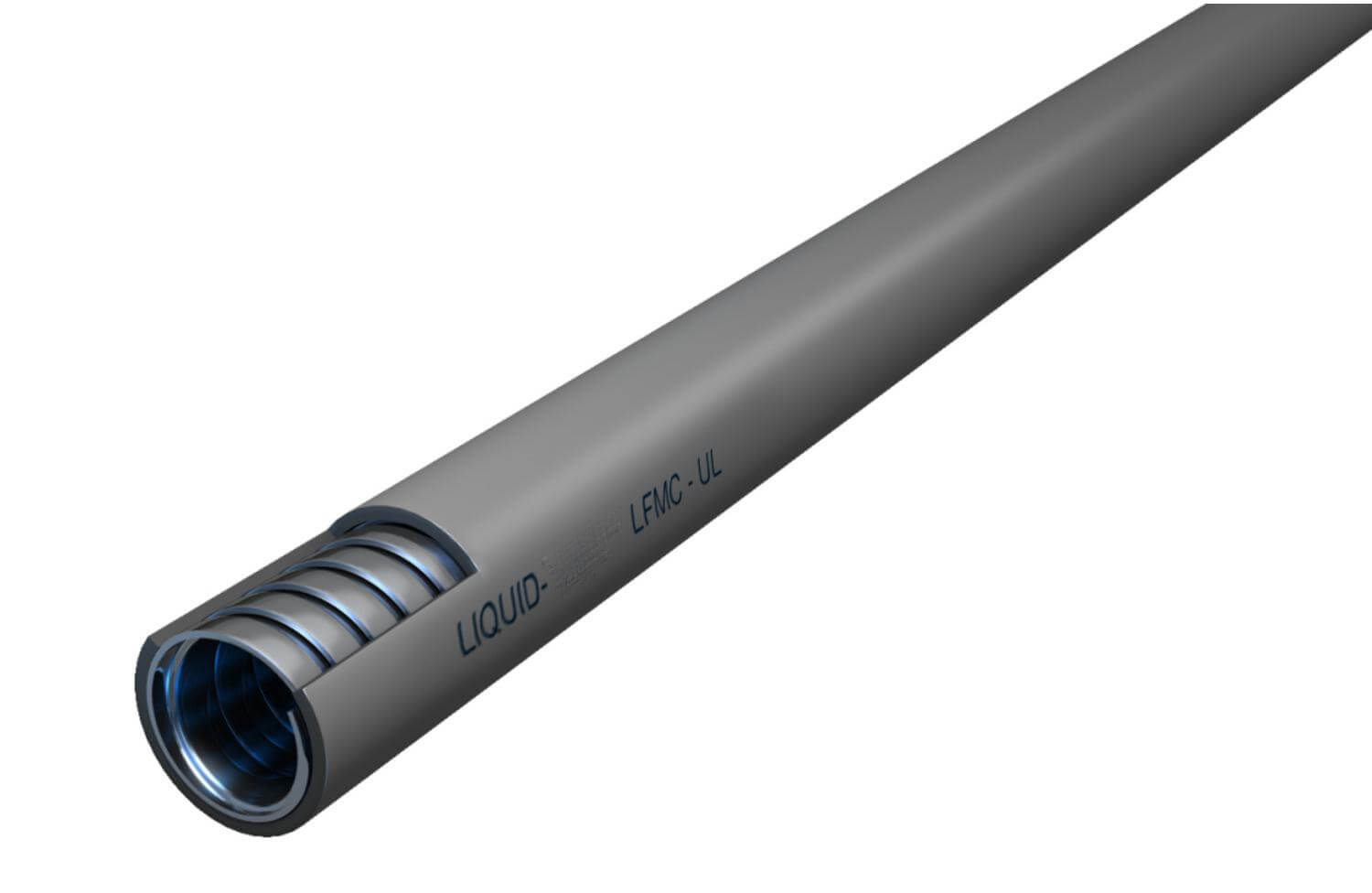

Liquidtight Flexible Metal Conduit (LFMC) – Similar to FMC but covered with a waterproof plastic coating, making it suitable for wet or outdoor environments.

Aluminum Conduit – A corrosion-resistant alternative to steel conduits, often used in environments where moisture is a concern, such as coastal areas.

5.1.2 Protective Coatings for Metal Conduits

To enhance durability and corrosion resistance, metal conduits are often treated with protective coatings. Some of them are the composite material conduit.

Galvanized Coating – Applied to steel conduits to prevent rust and corrosion, typically using hot-dip galvanization.

Epoxy Coating – Provides extra protection against chemicals and harsh environments, commonly used in industrial settings.

PVC Coating – Adds an extra layer of insulation and corrosion resistance, making it suitable for underground and outdoor installations.

Anodized Aluminum – Improves aluminum conduit resistance to oxidation, making it ideal for marine and humid environments.

5.1.3 Advantages and Disadvantages of Metal Conduits

Advantages:

Excellent mechanical protection for electrical wiring.

High resistance to fire and physical damage.

Provides electromagnetic shielding for sensitive electrical systems.

Suitable for harsh and industrial environments.

Disadvantages:

Heavier and more challenging to install compared to non-metallic conduits.

Susceptible to corrosion if not properly coated or maintained.

Requires grounding, adding complexity to installation.

5.1.4 Common Applications of Metal Conduits

Industrial Facilities – Protects wiring in factories and plants.

Commercial Buildings – Often used in office spaces and retail stores.

Hazardous Locations – Suitable for explosive or high-risk environments.

Outdoor Installations – RMC and IMC are commonly used in exposed locations.

5.2 PVC Conduit

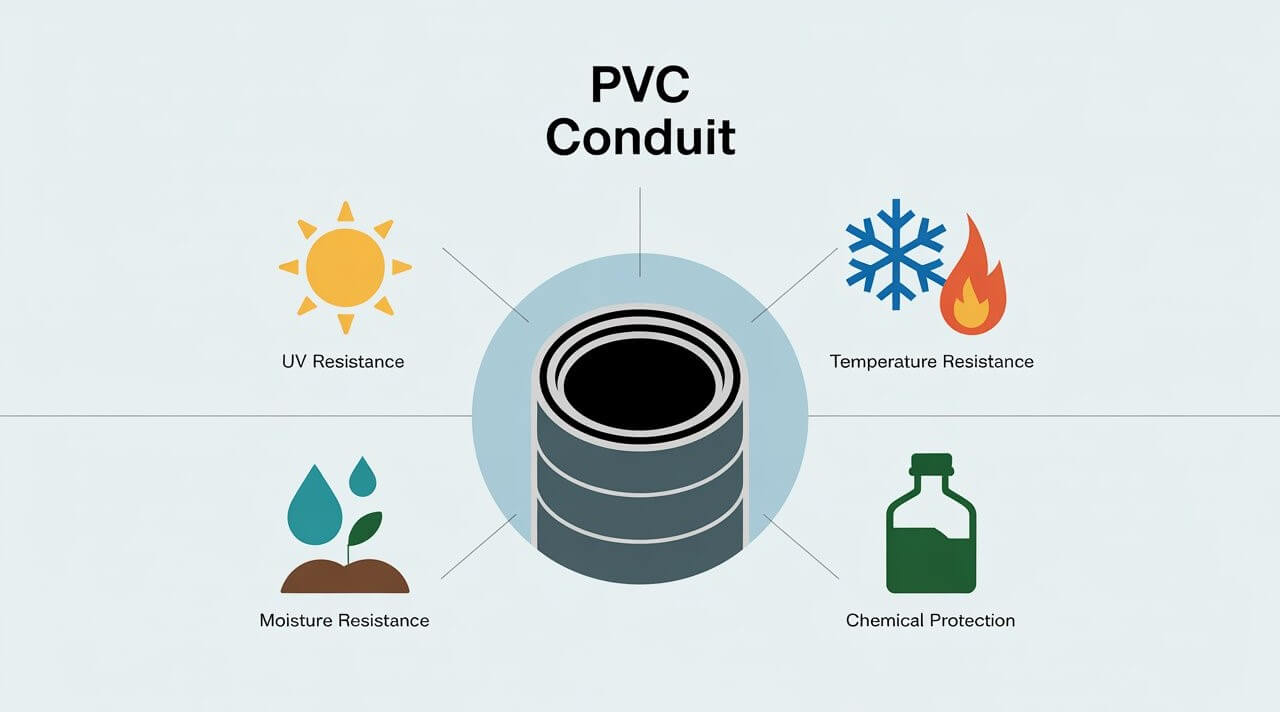

PVC (Polyvinyl Chloride) conduit is a widely used non-metallic alternative to metal conduit, offering advantages such as corrosion resistance, lightweight properties, and ease of installation. Unlike metal conduits, PVC does not conduct electricity, eliminating the need for grounding. This makes it a preferred choice for residential, commercial, and underground applications. Below, we explore the types of PVC conduit, their benefits, and potential limitations.

5.2.1 Types of PVC Conduit/Special Types

Rigid PVC Conduit (RPVC) – A durable, thick-walled conduit designed for underground and exposed applications. It is resistant to impact and moisture and is commonly used in direct burial and wet locations.

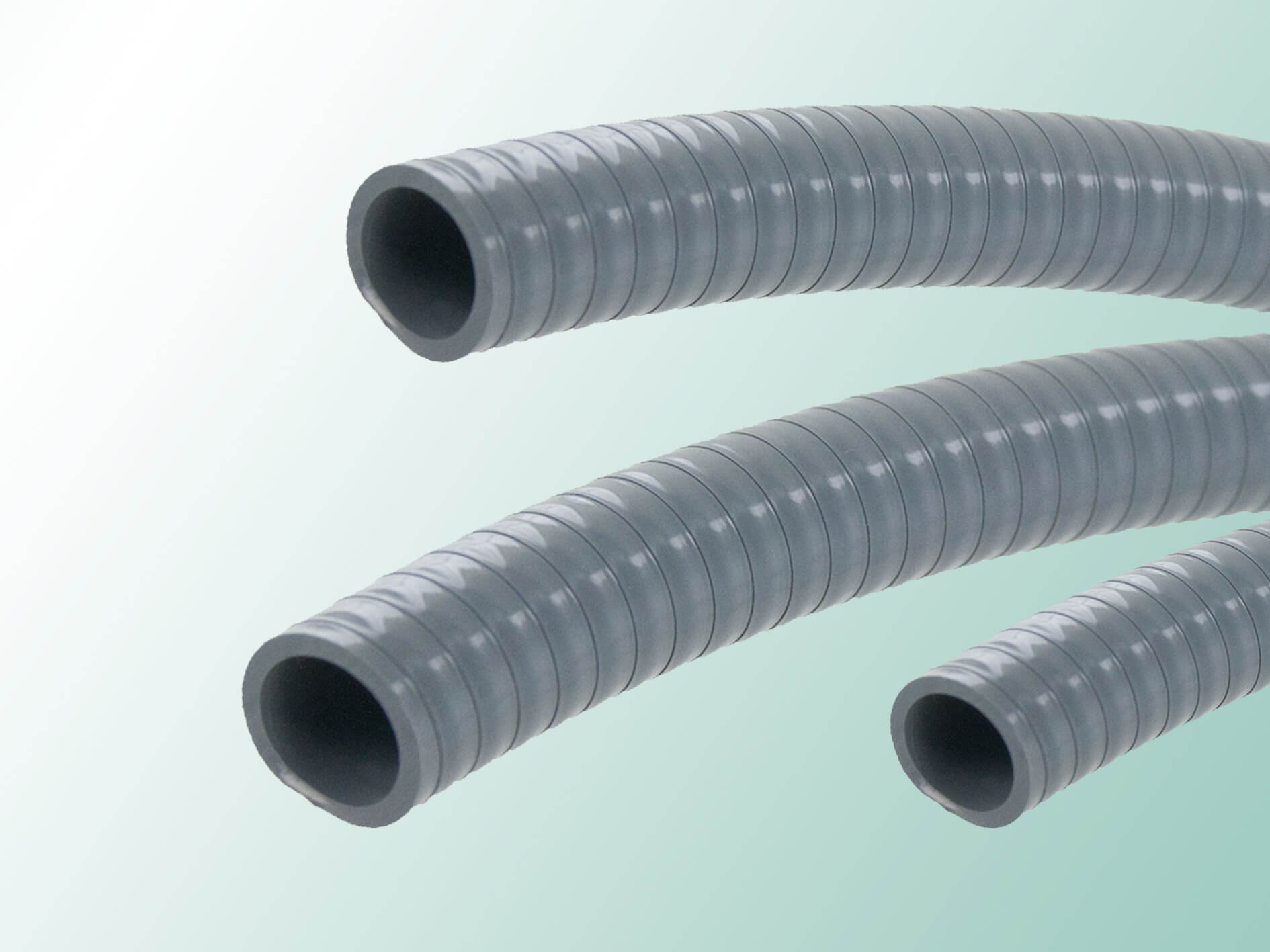

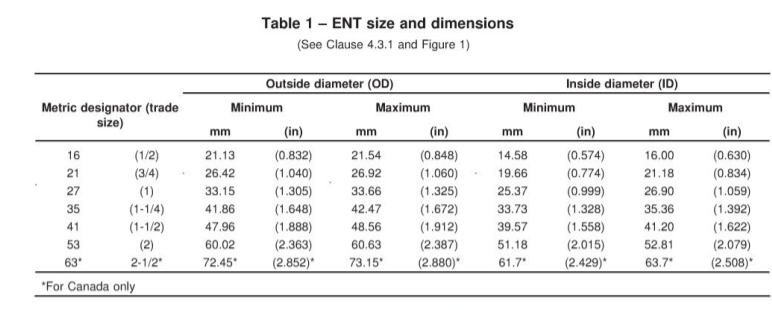

Electrical Non-metallic Tubing (ENT) – A flexible, corrugated PVC conduit that is lightweight and easy to bend. It is mainly used in indoor applications where quick and simple installation is required.

Solar UPVC Conduit – A UV-resistant, weatherproof conduit specifically designed for solar panel installations. It protects wiring from prolonged sun exposure, extreme temperatures, and harsh outdoor conditions, ensuring long-term performance in renewable energy systems.

LSZH (Low Smoke Zero Halogen) PVC Conduit – A specially formulated conduit designed for enclosed environments like tunnels, commercial buildings, and public transport systems. It minimizes toxic smoke and halogen emissions in case of fire, reducing health risks and equipment damage.

5.2.2 Advantages and Disadvantages of PVC Conduit

Advantages:

Corrosion and Chemical Resistance – Unlike metal conduit, PVC does not rust or corrode, making it ideal for humid and corrosive environments.

Lightweight and Easy to Install – PVC is much lighter than metal conduit, reducing labor and transportation costs. It can be easily cut and assembled using solvent cement.

Electrical Insulation – Since PVC is non-conductive, it does not require grounding, simplifying installation.

Weather and UV Resistance – Certain types of PVC conduit are UV-resistant, making them suitable for outdoor applications.

Cost-Effective – Generally more affordable than metal conduits, making it a budget-friendly option for various electrical installations.

Disadvantages:

Lower Mechanical Strength – PVC is not as impact-resistant as metal conduit, making it less suitable for areas with high mechanical stress.

Limited High-Temperature Resistance – PVC can warp or degrade under extreme heat, restricting its use in high-temperature environments.

Expansion and Contraction – PVC expands and contracts with temperature changes, requiring expansion joints in certain installations.

5.2.3 Common Applications of PVC Conduits

Residential Wiring – Used in homes for protecting electrical cables in walls, ceilings, and floors.

Commercial Installations – Ideal for office buildings, retail spaces, and warehouses where non-metallic protection is preferred.

Underground Systems – Frequently used for buried electrical lines due to its moisture resistance.

Wet and Corrosive Environments – Suitable for industrial settings exposed to chemicals or high humidity.

Renewable Energy Projects – Applied in solar and wind energy installations for efficient and long-lasting wiring protection.

6. Conclusion

Choosing between metal and PVC electrical conduits is not simply about determining which material is better—it depends on multiple factors, including compliance with industry standards, project-specific requirements, budget constraints, and environmental conditions. Each type of conduit has its advantages and ideal applications.

We hope this article has provided valuable insights to help you make an informed decision when selecting electrical conduit solutions for your needs.

About Ctube

Ctube is a leading manufacturer with over ten years of experience in the PVC cable ducting industry. We specialize in providing high-quality electrical conduit solutions, ensuring durability, safety, and compliance with international standards. Our AS/NZS 2053 standard conduits and Low Smoke Zero Halogen (LSZH) series wiring ducts meet IEC standards, hold necessary certifications, and have been rigorously tested by third-party laboratories.

If you are interested in learning more about our products or need guidance on choosing the right conduit, feel free to contact us. Thank you for reading!

IEC 61386 Standard PVC Conduit – Everything You Need to Know Read More »