1. Introduction Conduits are vital components in both electrical and communication systems, serving as protective pathways for cables and wires....

Read More

Blog

How to Choose the Right Electrical Conduit for Your Project by Application

Ctubeofficialchina – July 6, 2024

1. Introduction to Choosing the Right Electrical Conduit Project Choosing the right electrical conduit for your project is crucial...

Read More

What Electrical PVC Conduit Manufacturers are ISO 9001?

Ctubeofficialchina – June 17, 2024

In the dynamic world of electrical installations, the quality and reliability of components are paramount. Among these components, PVC conduits...

Read More

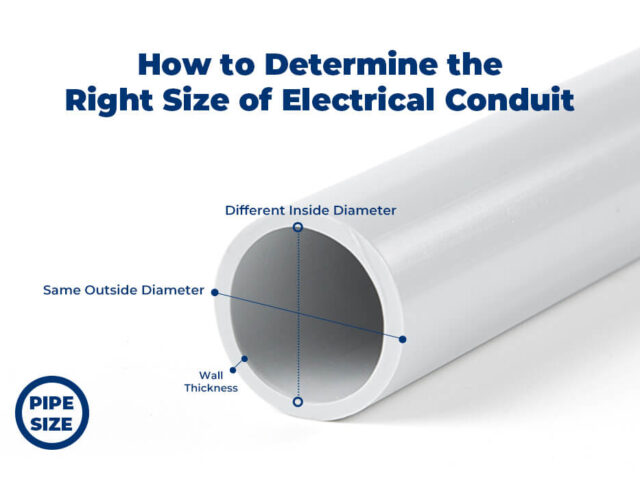

How to Determine the Right Size of Electrical Conduit

Ctubeofficialchina – May 24, 2024

Introduction Choosing the correct conduit size for your electrical projects is crucial for ensuring safety, efficiency, and compliance with building...

Read More

How to Choose the Conduit Size for Electrical Installations

Ctubeofficialchina – May 21, 2024

1. Introduction When planning an electrical installation—whether it's for your home, a commercial building, or an outdoor project—choosing the right...

Read More

Comparative Analysis of Above Ground and Below Ground Electrical Conduit Systems

Ctubeofficialchina – May 15, 2024

What is Above Ground Conduit? References to above ground conduits in this article are to conduits protect electrical installation placed...

Read More

Top LSZH Conduit Suppliers and Manufacturers In Chile 2025

Ctubeofficialchina – May 4, 2024

As industries and households alike prioritize fire safety and environmental consciousness, the demand for LSZH (Low Smoke Halogen Free) conduit...

Read More

6 Innovative PVC Conduit Fittings That Boost Efficiency

Ctubeofficialchina – April 16, 2024

Electrical conduit fittings are essential components in wiring systems, providing connectivity, protection, and organization for electrical conduits. In this article,...

Read More

Top 10 Electrical Conduit Suppliers and Manufacturers in Australia and New Zealand

Ctubeofficialchina – April 13, 2024

Electrical conduit plays a vital yet often overlooked role in the safe delivery of power to homes, businesses and infrastructure...

Read More

Electrical Rigid Conduit Comparison: PVC Conduit vs Metal Conduit (EMT, RMC, IMC)

Ctubeofficialchina – April 12, 2024

1. Introduction: Why Electrical Rigid Conduit Matters If you wants to understand the key differences between rigid conduit made of...

Read More

Endless Options For Your Specific Needs

Ctube focuses on the plastic electrical conduit field, around the customer’s demand for products, technology and services.

We always take additional measures to make our customers satisfied with the quality, efficiency and marketability of our products. With high quality and a wide range of products, we have established long-term cooperation with many customers from different areas of the world.

Request a Quote

Ready to Work Together? Build a project with us!