1. ABB (Switzerland) Company Overview ABB Ltd, headquartered in Zurich, Switzerland, is a global leader in electrification and automation technologies....

Read More

Blog

Top 10 Electrical Box Brands and Manufacturers in the World 2025

Ctubeofficialchina – January 8, 2025

How Temperature Affects PVC Electrical Conduit Pipes

Ctubeofficialchina – December 25, 2024

1. Introduction 1.1 What are PVC Electrical Conduit Pipes? PVC (Polyvinyl Chloride) electrical conduit pipes are rigid or flexible...

Read More

Conduit Fittings Electrical Conduit Pipe Electrical Metallic Tubing Electrical Nonmetallic Tubing Industry News

How to Connect Flexible Conduit to an Electrical Box: A Step-by-Step Guide

Ctubeofficialchina – December 16, 2024

1. Introduction Flexible conduit is a versatile and essential component in modern electrical systems, offering protection and flexibility for wires...

Read More

Top 10 Electrical Conduit Pipe Suppliers in Brazil

Ctubeofficialchina – November 1, 2024

Electrical conduits play a vital role in construction and infrastructure, serving as protective pathways for electrical wiring and ensuring the...

Read More

Conduit Fittings Electrical Conduit Pipe Electrical Metallic Tubing Electrical Nonmetallic Tubing Industry News

Choosing the Right Flexible Electrical Conduit for Outdoor Use: A Comprehensive Guide

Ctubeofficialchina – October 14, 2024

1. Introduction Can flexible conduit be used outdoors? The answer is yes! 🌞But to make sure your outdoor wiring stays...

Read More

Top 10 China PVC Pipe Manufacturers and Suppliers in 2025

Ctubeofficialchina – September 27, 2024

1.LESSO China Lesso Group Holdings Limited stands as a leading industrial group in China, specializing in home furnishings and...

Read More

Conduit Fittings Electrical Conduit Pipe Electrical Metallic Tubing Electrical Nonmetallic Tubing fiberglass conduit Industry News

Top 10 Electrical Conduit Pipe Suppliers in Singapore

Ctubeofficialchina – September 11, 2024

1. Cantex Company Values and Vision Cantex Inc. is a distinguished name in the electrical conduit industry, recognized for...

Read More

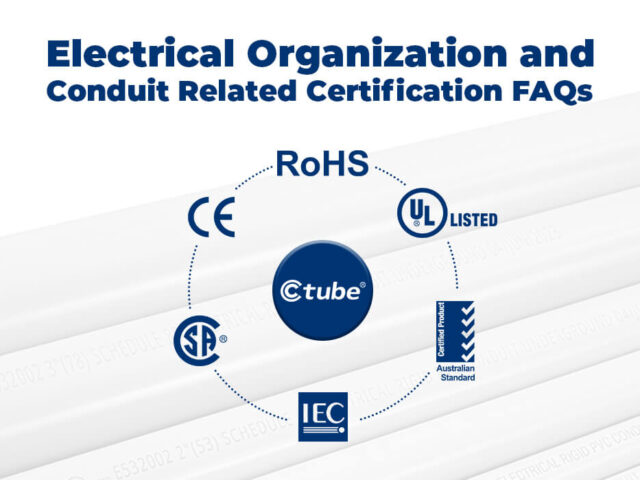

Electrical Organization and Conduit Related Certification FAQs, Every thing You need to Know

Ctubeofficialchina – August 27, 2024

In industries dominated by electrical products, such as the electrical conduit industry, adhering to stringent manufacturing standards is absolutely essential....

Read More

Top 10 Electrical Conduit Manufacturers in Mexico

Ctubeofficialchina – August 3, 2024

1. Atkore Atkore is a leading global manufacturer and distributor of electrical raceway products and solutions. With a rich history...

Read More

Everything You Need To Know About Electrical Conduit Size

Ctubeofficialchina – July 25, 2024

1. Introduction Electrical conduits are essential components in modern electrical systems, serving as protective tubing for electrical wiring. They safeguard...

Read More

Endless Options For Your Specific Needs

Ctube focuses on the plastic electrical conduit field, around the customer’s demand for products, technology and services.

We always take additional measures to make our customers satisfied with the quality, efficiency and marketability of our products. With high quality and a wide range of products, we have established long-term cooperation with many customers from different areas of the world.

Request a Quote

Ready to Work Together? Build a project with us!