1. Introduction 👀 Ever stood in front of a row of PVC conduits—grey, orange, black, white, even red—and wondered which...

Read More

Blog

5 Benefits of Using PVC Electrical Conduit in Your Next Project

Ctubeofficialchina – April 22, 2023

1. Introduction to Electrical Conduit Pipe In modern electrical installations, choosing the right conduit material is a critical decision that...

Read More

The Impact of UV Exposure on PVC Conduit Pipes

Ctubeofficialchina – April 20, 2023

PVC (Polyvinyl chloride) conduit pipes are commonly used for electrical wiring and cable protection in buildings, homes, and industrial settings. However,...

Read More

The Benefits of Using PVC Conduit Pipes for Renewable Energy Applications

Ctubeofficialchina – April 19, 2023

With the increasing use of renewable energy sources such as solar, wind, and hydro power, it is becoming more important...

Read More

Understanding PVC Conduit Fill Charts: A Comprehensive Guide (2025)

Ctubeofficialchina – April 18, 2023

1. Introduction When talking about electrical conduit, most people focus on the obvious choices—what material to use, which type to...

Read More

TOP 10 PVC CONDUIT MANUFACTURER AND SUPPLIER 2025

Ctubeofficialchina – April 18, 2023

PVC conduit plays a vital role in electrical installations, providing a safe and protective pathway for electrical wires and cables....

Read More

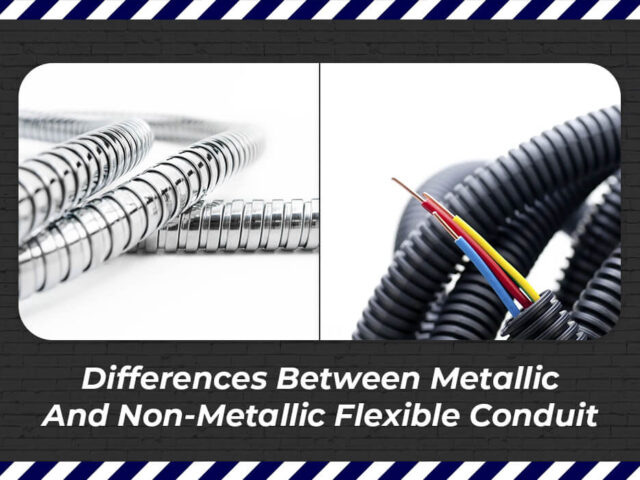

Differences between Metallic and Non-Metallic Flexible Conduit

Ctubeofficialchina – April 15, 2023

Electrical wiring requires protection from physical damage, moisture, dust, and other hazards. Flexible conduit is an excellent solution for these...

Read More

All About the Colors of PVC Conduit?

Ctubeofficialchina – April 14, 2023

If you’re working with electrical wiring, chances are you’ve come across PVC conduit before. PVC conduit is a plastic tubing...

Read More

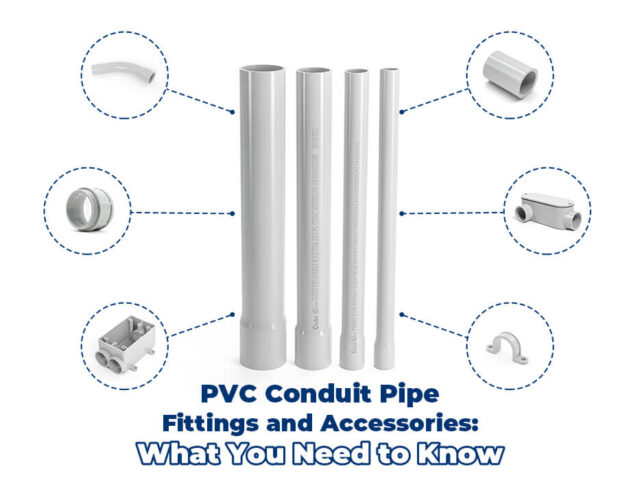

PVC Conduit Pipe Accessories: What You Need to Know

Ctubeofficialchina – April 12, 2023

I. Introduction PVC conduit pipes are commonly used to protect and route electrical wiring in both residential and commercial settings....

Read More

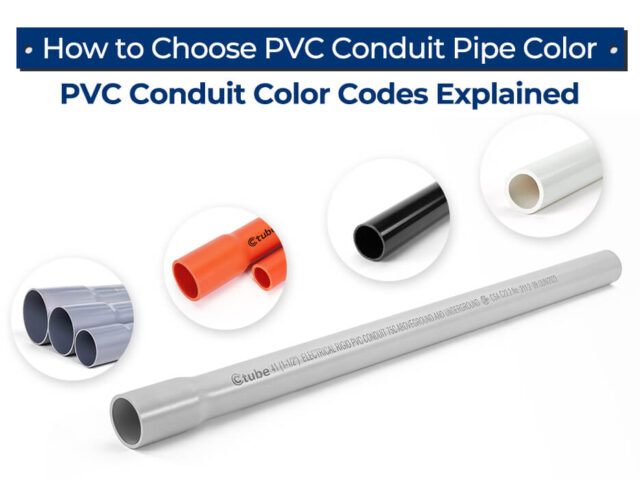

How to Choose PVC Conduit Pipe Color: PVC Conduit Color Codes Explained

Ctubeofficialchina – April 10, 2023

1. Introduction 🛠️ When planning any electrical or communication project, there’s more to think about than just wires and voltage....

Read More

Endless Options For Your Specific Needs

Ctube focuses on the plastic electrical conduit field, around the customer’s demand for products, technology and services.

We always take additional measures to make our customers satisfied with the quality, efficiency and marketability of our products. With high quality and a wide range of products, we have established long-term cooperation with many customers from different areas of the world.

Request a Quote

Ready to Work Together? Build a project with us!