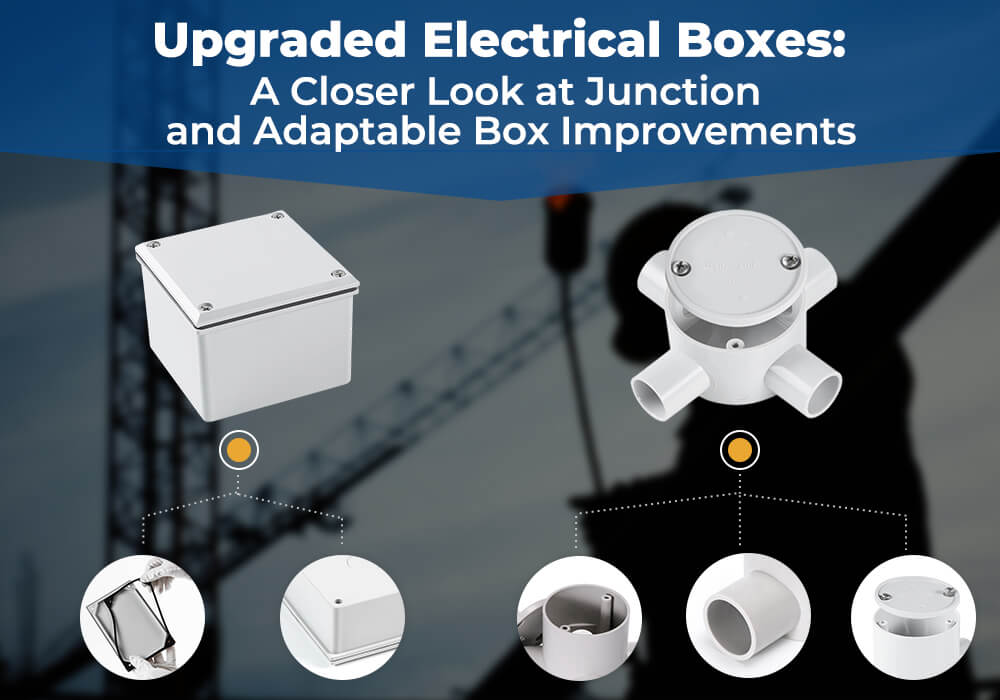

Upgraded Electrical Boxes: A Closer Look at Junction Box and Adaptable Box Improvements

1. Introduction

If you’re working on an electrical project that demands safety, performance, and compliance with AS/NZS 2053 standards, choosing the right electrical box is essential.

At Ctube, we continue to innovate by upgrading our adaptable and junction boxes to better serve installers, engineers, and contractors across Australia and New Zealand.

In this post, we take a closer look at the latest enhancements made to our AS/NZS 2053 adaptable electrical boxes — from corrosion-resistant materials to time-saving features designed for easier, safer installations.

2. AS/NZS 2053 Electrical Adaptable Box Improve Design

🔩 Stainless Steel Screws for Electrical Boxes – Built to Last

Many electrical box manufacturers use galvanized screws, which may corrode over time—especially in outdoor or humid environments. Ctube’s adaptable boxes are equipped with premium stainless steel screws, offering excellent corrosion resistance and long-term durability. This ensures secure, lasting installations that stand up to the elements.

🔧 Long Anti-Drop Screws – No More Lost Hardware During Installation

Our long screw design solves a common frustration: dropped or lost screws during installation. These screws stay firmly in place even when the lid is open, helping engineers and electricians work faster without interruptions. It’s a simple but effective solution that boosts productivity and reduces the chance of errors on-site.

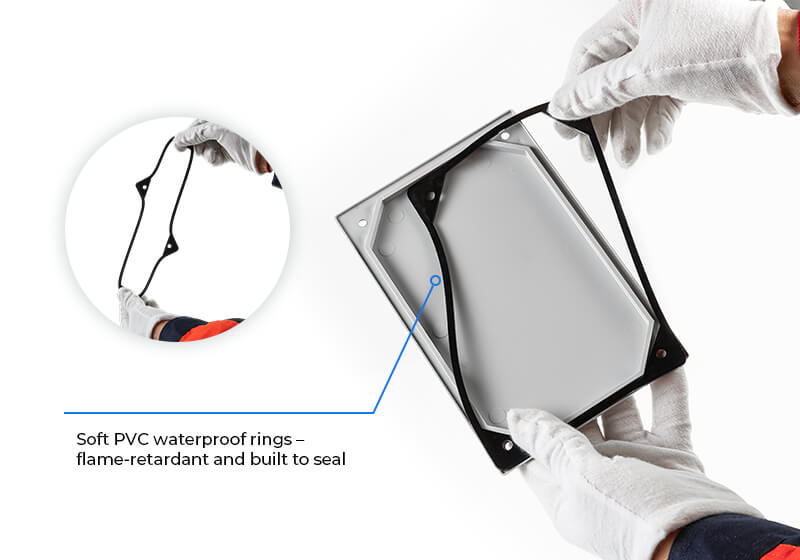

💧 Soft PVC Waterproof Sealing Rings – Enhanced Protection & Fire Resistance

Waterproofing is a non-negotiable feature in any electrical box—especially in outdoor or damp environments. While rubber sealing rings are commonly used, we’ve upgraded to flexible soft PVC, which offers both superior waterproof performance and flame-retardant properties. This dual protection makes our boxes ideal for high-safety environments.

📏 Internal Guide Columns – Accurate, Time-Saving Drilling

Inside the box, you’ll find uniformly distributed internal columns. These aren’t just structural supports—they act as guide points for direct drilling, allowing for fast, precise hole placement. Engineers can easily align the box without guesswork, ensuring stronger sealing and faster installation.

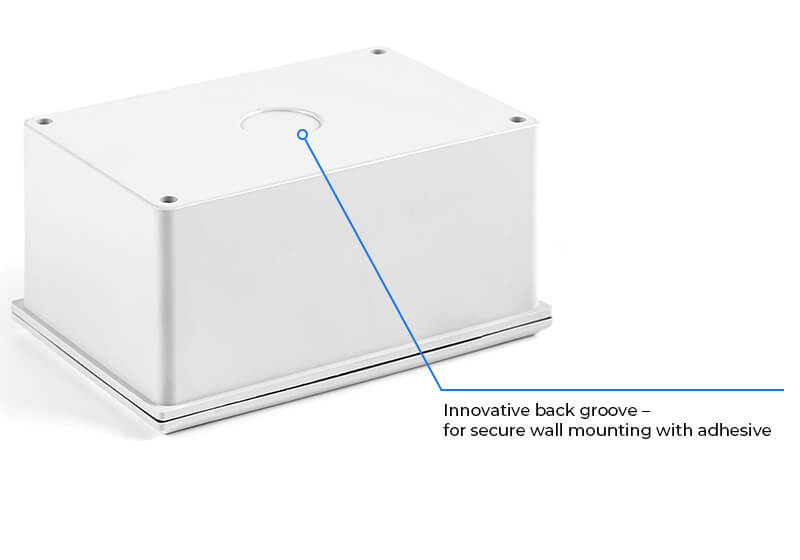

🧱 Innovative Back Groove Design – Easy Surface Mounting with Adhesive

Need to mount your box to a wall or flat surface without screws? Our back groove design makes that simple. The groove provides a flush contact area for glue-based mounting, offering strong adhesion to both vertical and horizontal surfaces. This makes it ideal for surface-mount electrical box applications in tight or finish-sensitive areas.

📌 Each of these features—stainless steel screws, waterproof PVC rings, guide columns, and adhesive mounting—has been carefully engineered to meet the demands of modern electrical installation work in AS/NZS 2053 environments.

By combining compliance, safety, and efficiency, Ctube adaptable boxes help professionals deliver better results with less effort.

3. AS/NZS 2053 Electrical Junction Box Sizes & Smart Features Explained

A junction box is a vital component in any electrical system. It acts as a central hub where wires connect, allowing circuits to function safely and efficiently.

At Ctube, we have enhanced the design of our AS/NZS 2053-compliant junction boxes to make installation faster, safer, and more flexible for engineers and contractors across different applications.

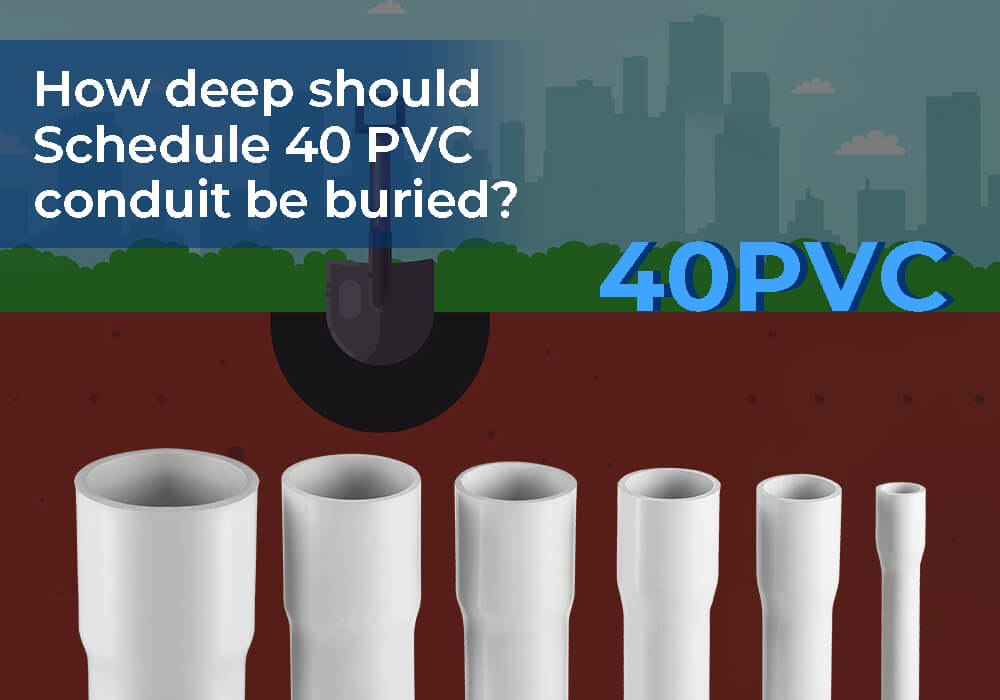

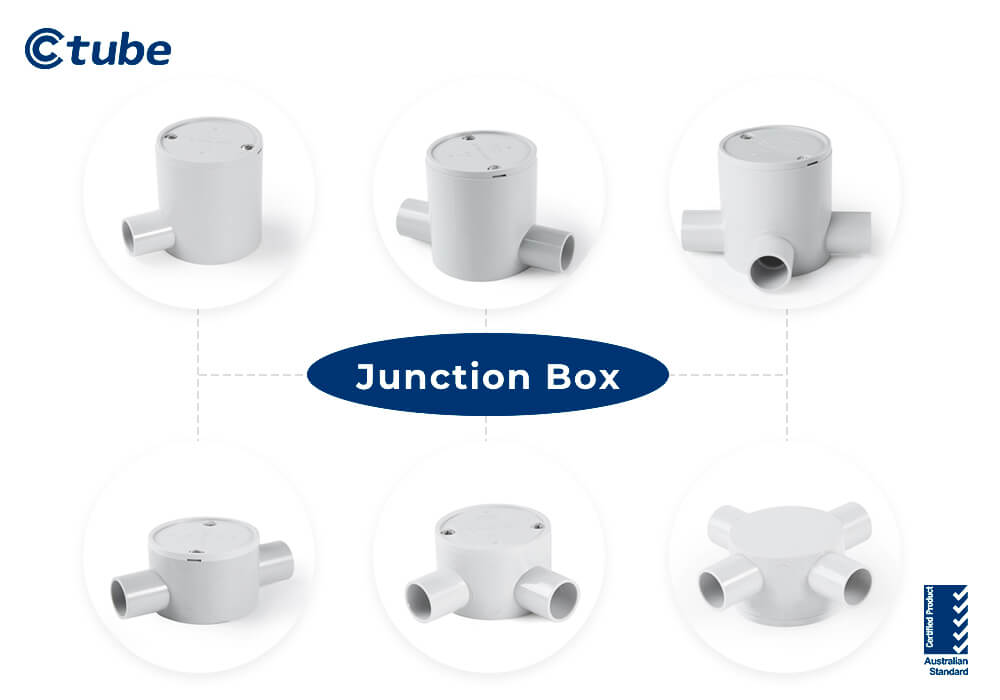

📦 Multiple Sizes & Configurations – More Options for Every Project

At Ctube, we understand that different electrical installations require different junction box setups.

✅ Shallow junction boxes – ideal for limited space applications

✅ Deep junction boxes – for added wiring room and flexibility

One-way, Two-way, Three-way, Four-way, and Right-angle – giving you more options for conduit direction and layout.

To suit standard conduit systems, all models come in 20 mm and 25 mm sizes.

And if your project has unique requirements, we also offer customization options to ensure the perfect fit.

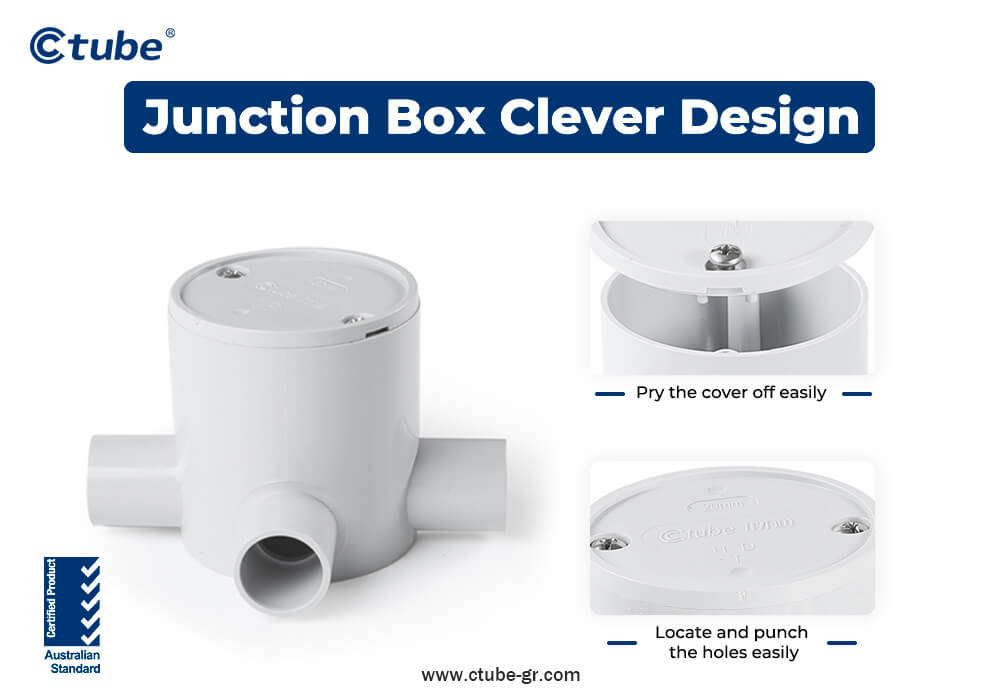

🔧 Easy-Open Lid Design – Time-Saving for Engineers

Installation and inspection often require repeated opening and closing of the junction box lid. To make this process easier, we’ve added a small gap in the lid edge—just enough to allow a screwdriver tip to fit in, so engineers can open the lid quickly and without damage.

This simple design change helps reduce installation and maintenance time in the field.

🎯 Lid Groove for Accurate Drilling – Better Positioning, Fewer Errors

One of the standout features is a precision groove on the lid surface. This small but effective detail helps engineers easily mark and drill positioning holes, reducing measurement time and minimizing errors during mounting.

Whether you’re working in a confined space or aiming for perfectly aligned installations, this feature makes the job easier and cleaner.

4. Conclusion

Whether you’re upgrading existing systems or starting a new electrical installation, choosing the right junction and adaptable boxes can significantly impact performance, safety, and efficiency.

Ctube’s AS/NZS 2053-compliant designs offer smart features, durable materials, and flexible options to meet the demands of modern electrical work.

With thoughtful innovations, we help engineers and contractors work smarter, faster, and safer.

👉 Contact Ctube to request a sample or download detailed technical specifications.

Preguntas frecuentes

1. Can I use a junction box for both indoor and outdoor installations?

Only if the box is rated for outdoor use. Outdoor junction boxes need to be weatherproof and sealed against water and dust. Always check the label or rating—indoor boxes aren’t suitable for outdoor conditions.

2. How do I determine the correct box volume for the number of wires?

You need to match the box size with how many wires and devices go inside. Each wire and device takes up space, and the box should be big enough to avoid overcrowding. Look for the cubic inch rating on the box and follow local code guidelines.

3. How often should junction boxes be inspected?

For homes, check every few years or during renovations. In outdoor or commercial settings, it’s safer to inspect more often—once a year is a good rule. Also check if you notice any signs of overheating or loose connections.

Upgraded Electrical Boxes: A Closer Look at Junction Box and Adaptable Box Improvements Leer más "