1. Introduction Lors de la réalisation d'un projet électrique, il est courant d'acheter les câbles et les conduits ensemble. En fait, beaucoup...

En savoir plus

Blog

Comment cintrer un conduit électrique sans cintreuse

Ctubeofficialchine – 22 juillet 2025

1. Introduction “ Peut-on cintrer un conduit électrique sans outil spécial ? ” C’est une question fréquente chez les personnes travaillant dans le domaine de l’électricité….

En savoir plus

Ce qu'il faut savoir avant d'installer un conduit exposé

Ctubeofficialchine – 5 juillet 2025

1. Introduction Lorsqu'on pense aux conduits électriques, on les imagine souvent dissimulés derrière les murs ou les plafonds. Mais dans de nombreux cas….

En savoir plus

Guide complet des coudes et des courbes en PVC dans les systèmes de conduits électriques

Ctubeofficialchine – 5 juillet 2025

1. Introduction Dans tout système de conduits électriques, les tronçons rectilignes ne sont que le point de départ. Pour contourner les angles, il faut éviter les obstacles structurels...

En savoir plus

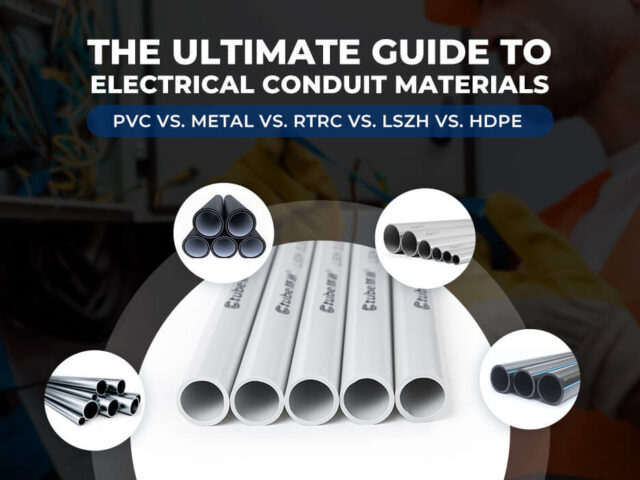

PVC vs. Métal vs. RTRC vs. LSZH vs. PEHD : Le guide ultime des matériaux pour conduits électriques (2025)

Ctubeofficialchine – 2 avril 2025

1. Introduction Un conduit électrique est un système de tubes de protection conçu pour abriter et protéger le câblage électrique contre les chocs mécaniques.

En savoir plus

Guide ultime des chemins de câbles : types de conception, tailles, réglementations et meilleures pratiques

Ctubeofficialchine – 31 mars 2025

1. Introduction aux systèmes de goulottes de câbles Les goulottes de câbles sont un élément essentiel des installations électriques, conçues pour abriter et protéger...

En savoir plus

Conduits en PVC conformes à la norme IEC 61386 : tout ce que vous devez savoir

Ctubeofficialchine – 24 mars 2025

1. Introduction Lorsqu'il s'agit d'installations électriques, le choix du bon conduit est crucial pour garantir la sécurité, la durabilité et les performances.

En savoir plus

Top 10 des fabricants et fournisseurs de tuyaux PPR en Chine

Ctubeofficialchine – 1 mars 2025

1. 联塑 (Groupe LESSO) Présentation : Créé en 1986 et coté à la Bourse de Hong Kong (HKEX : 2128), le Groupe LESSO...

En savoir plus

Les 10 premiers fabricants et fournisseurs de tubes PPR au monde

Ctubeofficialchine – 1 mars 2025

Les tuyaux en PPR (polypropylène copolymère aléatoire) sont devenus une pierre angulaire des infrastructures modernes en raison de leur durabilité, de leur résistance à la corrosion et...

En savoir plus

Raccords de conduits Tuyau de conduit électrique Tubes métalliques électriques Nouvelles de l'industrie

Guide pour sélectionner le meilleur conduit pour votre projet de fibre optique

Ctubeofficialchine – 1 février 2025

1. Introduction 1.1 Aperçu des installations de fibre optique La technologie de la fibre optique est l'épine dorsale de la communication moderne, permettant l'Internet haut débit,...

En savoir plus

Des options infinies pour vos besoins spécifiques

Ctube se concentre sur le domaine des conduits électriques en plastique, autour de la demande des clients en matière de produits, de technologies et de services.

Nous prenons toujours des mesures supplémentaires pour que nos clients soient satisfaits de la qualité, de l'efficacité et de la qualité marchande de nos produits. Avec une haute qualité et une large gamme de produits, nous avons établi une coopération à long terme avec de nombreux clients de différentes régions du monde.

Demander un devis

Prêt à travailler ensemble ? Construisez un projet avec nous !