جدول المحتويات

تبديل1 المقدمة

In any electrical conduit system, straight runs of pipe are just the beginning. To navigate corners, avoid structural obstacles, or follow the layout of a building, PVC elbows and bends become essential components for effective navigation. While often overlooked compared to conduit pipes themselves, these fittings play a critical role in maintaining system integrity, ease of installation, and long-term safety.

PVC turning preformed connectors designed to guide conduit around corners and help installers achieve smooth directional changes without stressing the wire or the conduit. They enable clean transitions, reduce the risk of wire damage during pulling, and help projects meet strict electrical code requirements.

From residential wiring layouts to complex underground utility systems, PVC elbows are everywhere. Available in various angles and sizes, these simple yet indispensable fittings are specifically engineered to meet performance standards like UL 651, CSA C22.2, and other global certifications.

In this post, we’ll take a deep dive into the world of PVC elbows and bends—what they are, how they’re used, which standards govern them, and why choosing the right type makes all the difference in a professional conduit installation.

2. Product Structure & Types of PVC Elbows and Bends

In a conduit system, directional changes are inevitable—whether you’re navigating walls, columns, or underground obstacles. That’s where PVC elbows and bends come into play. Although they may seem like simple fittings, their structure, angle, and radius have a big impact on installation, wire pulling, and long-term system performance.

✅ PVC Elbow

A rigid, pre-molded fitting with a fixed angle—most commonly 90° or 45°.

Typically has bell ends for easy solvent cement connections.

Ideal for tight turns, such as inside walls, near panels, or limited-space installations.

Offers precision and structural rigidity, but creates sharper cable turns.

✅ PVC Bend

Refers to a curved piece of conduit, either bent on-site (using heat or bending tools) or supplied pre-bent by the factory —also called sweep bend or pre-formed bends.

Has a longer turning radius, allowing for smoother directional changes.

Reduces stress on wires, making it suitable for longer cable runs or sensitive conductors.

More flexible in layout design but may require more space.

3. Installation Guidelines and Code Compliance

Proper installation of PVC elbows and bends is not just about getting the right fit—it’s also about staying compliant with electrical codes, ensuring safety, and making cable pulling easier.

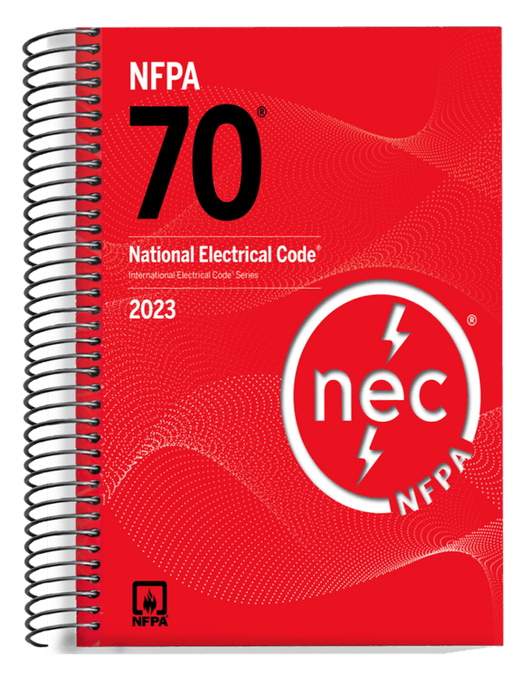

📘 NEC (National Electrical Code – USA)

The NEC outlines very clear rules for how and when elbows or bends can be used in a conduit run.

Total Bend Limit: According to NEC 352.26, the total sum of bends between pull points must not exceed 360°.

That means: you can use up to four 90° elbows, or eight 45° bends between boxes or pull points.

If the total angle exceeds this, you need to add a junction box or pull box.

Minimum Bending Radius: NEC 352.24 states that PVC conduit must be bent without kinking and must meet the minimum radius based on the conduit diameter. This also applies to elbows and sweep bends:

For example, a 2″ Schedule 40 conduit requires a radius of at least 16″ when bent.

Using long-radius sweep elbows helps meet this requirement easily.

Use of Factory Elbows: NEC allows the use of listed (UL-certified) elbows and bends, especially for buried or exposed installations. Field-bent conduit must meet the same radius and wall integrity standards.

📗 CSA (Canada) – C22.2 No. 211.2

In Canada, the CSA standard for nonmetallic fittings includes similar requirements:

Bends must not reduce the internal diameter or weaken the conduit wall.

Elbows used with DB2, Rigid PVC, or ENT must be CSA-certified to ensure safe performance in cold weather, moisture, and direct burial.

Marking is required: Bends and elbows must show size, type, and certification mark.

4. Certification Standards and Performance Requirements

🔵 UL 651 (USA) – Schedule 40 & 80 PVC Conduit and Fittings

🔵 CSA C22.2 No. 211.2 (Canada) – PVC Conduit Fittings

🌐 IEC 61386 (International) – Conduit Systems for Cable Management

🟢 AS/NZS 2053 (Australia/New Zealand)

Under UL 651, all rigid PVC conduit fittings—including elbows, bends, couplings, and expansion joints—must pass a range of safety and performance tests. These tests evaluate resistance to heat, impact, moisture, and aging, while ensuring structural integrity and correct dimensions.

If a fitting differs from an approved design—by shape, size, or material—it must be retested. Key retests include arc resistance, chemical response, mechanical stability, and installation performance.

Checks if the fitting absorbs moisture that might reduce insulation performance.

The fitting is exposed to a controlled gas flame. It must self-extinguish within 5 seconds, produce no flaming drips, and must not burn through completely.

Fittings are heated to 92°C (198°F) for one hour and must keep their shape. Size variation must be within 15% and no cracking should occur.

After 5 minutes in acetone, the surface should show no peeling, cracking, or poor fusion, confirming material and process quality.

Fittings are compressed under steel plates. They must retain at least 70% of their inner diameter and must not collapse.

After bending, the fitting must still hold firmly to the conduit when pulled under tension.

Fittings like non-metallic service entrance heads undergo:

• Simulated rainfall test

• UV + water exposure (1000 hours)

• Long-term heat aging

• Impact tests at room and freezing temperatures

These are tested in realistic conditions with:

• 500 cycles of movement

• Angular deflection

• Wet location retest afterward (if outdoor-rated)

• المقاومة للتآكل for any metal parts like screws or plates

Must pass:

• Flame resistance even after moisture or UV exposure

• 70% retention of strength and flexibility after aging

• Lab verification (e.g., IR spectroscopy) for material identity

• For underground/outdoor use: verify crush, wet location, UV test compliance

• For indoor/fire-rated use: ensure flammability and pull strength approval

• If metal or rubber parts are used, look for extra testing (corrosion, elastomer durability)

5. الخاتمة

PVC elbows and bends may seem like simple components in an electrical conduit system—but as we’ve seen throughout this guide, their role is far from minor.

From managing direction changes to maintaining bend radius and meeting strict code requirements, these fittings are essential for safety, functionality, and ease of installation. Whether you’re wiring a residential home, laying underground utilities, or installing solar infrastructure, choosing the right type of elbow or sweep bend can make the difference between a smooth project and a costly complication.

In today’s market, the demand for certified, application-specific, and environmentally resilient fittings continues to rise. Products that meet UL, CSA, or IEC standards are no longer optional—they’re expected.

كتوب is a trusted global manufacturer of PVC conduit systems and fittings, with over 10 years of industry experience.

Whether you’re a contractor, engineer, distributor, or OEM, we’re here to support your next project with certified, high-quality products.